Specs at a glance

-

Max. measurement error

Volume flow (standard): ±0.5 % o.r.± 1 mm/s (0.04 in/s)

Volume flow (option): ±0.2 % o.r. ± 2 mm/s (0.08 in/s), Flat Spec -

Measuring range

4 dm³/min to 9600 m³/h (1 gal/min to 44 000 gal/min)

-

Medium temperature range

Liner material PFA: –20 to +150 °C (–4 to +302 °F)

Liner material PFA high-temperature: –20 to +180 °C (–4 to +356 °F)

Liner material PTFE: –40 to +130 °C (–40 to +266 °F) -

Max. process pressure

PN 40, Class 300, 20K

-

Wetted materials

Liner: PFA; PTFE

Electrodes: 1.4435 (316L); Alloy C22, 2.4602 (UNS N06022); Tantalum; Platinum;

Titanium; Duplex 1.4462 (UNS S31803)

Field of application

Promag P is dedicated to chemical and process applications with corrosive liquids and highest medium temperatures. With its innovative remote transmitter Promag P 500 maximizes installation flexibility and operational safety in demanding environments. Heartbeat Technology enables compliance and process safety at all times.

The bidirectional measuring principle is virtually independent of pressure, density, temperature and viscosity

Dedicated to chemical and process applications with corrosive liquids and high medium temperatures

Device properties

Nominal diameter: max. DN 600 (24")

All common Ex approvals

Liner made of PTFE or PFA

Remote version with up to 4 I/Os

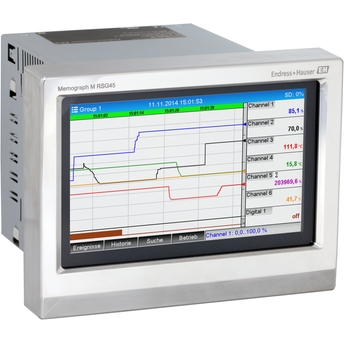

Backlit display with touch control and WLAN access

Standard cable between sensor and transmitter

Benefits

Diverse applications – wide variety of wetted materials

Energy-saving flow measurement – no pressure loss due to cross-section constriction

Maintenance-free – no moving parts

Full access to process and diagnostic information – numerous, freely combinable I/Os and Ethernet

Reduced complexity and variety – freely configurable I/O functionality

Integrated verification – Heartbeat Technology

Videos

Extended selection

-

High-end products

- Highly functional and convenient

Technical excellence

Simplicity

-

Standard products

- Reliable, robust and low-maintenance

Technical excellence

Simplicity

-

Specialized products

- Designed for demanding applications

Technical excellence

Simplicity

Variable

| FLEX selections | Technical excellence | Simplicity |

|---|---|---|

Fundamental selection Meet your basic measurement needs |

Technical excellence

|

Simplicity

|

Lean selection Handle your core processes easily |

Technical excellence

|

Simplicity

|

Extended selection Optimize your processes with innovative technologies |

Technical excellence

|

Simplicity

|

Xpert selection Master your most challenging applications |

Technical excellence

|

Simplicity

Variable |

Loading alternative products

Loading alternative products

Predecessor

-

-

Technical Information (TI)

Proline Promag P 500

English version - 08/2022

Electromagnetic flowmeter

EN 01/08/202214/08/202016/09/201915/07/201901/11/2018Language:

English

Version:

01/08/2022

File size:

11.3 MB

File name:

TI01226DEN_0922-00.pdf

-

-

-

Operating Instruction (BA)

Proline Promag P 500

English version - 08/2022

Electromagnetic flowmeter HART

EN 01/08/202214/08/202001/09/201915/12/201702/10/2017Language:

English

Version:

01/08/2022

File size:

9.6 MB

File name:

BA01399DEN_0622-00.pdf

-

-

-

Technical Information (TI)

Proline Promag P 500

Electromagnetic flowmeter

EN 01/08/202214/08/202016/09/201915/07/201901/11/2018Language:

English

Version:

01/08/2022

File size:

11.3 MB

File name:

TI01226DEN_0922-00.pdf

-

-

-

Operating Instruction (BA)

Proline Promag P 500 PROFIBUS PA

Electromagnetic flowmeter

EN 14/08/202001/11/201815/12/201701/08/2016Language:

English

Version:

14/08/2020

File size:

8.3 MB

File name:

BA01405DEN_0420.pdf

-

-

-

Operating Instruction (BA)

Proline Promag P 500 EtherNet/IP

Electromagnetic flowmeter

EN 14/08/202015/12/201702/10/2017Language:

English

Version:

14/08/2020

File size:

9.7 MB

File name:

BA01721DEN_0320.pdf

-

-

-

Operating Instruction (BA)

Proline Promag P 500 PROFINET

Electromagnetic flowmeter

EN 14/08/202016/09/201915/07/201915/12/201702/10/2017Language:

English

Version:

14/08/2020

File size:

11.7 MB

File name:

BA01724DEN_0520.pdf

-

-

-

Operating Instruction (BA)

Proline Promag P 500 PROFIBUS DP

Electromagnetic flowmeter

EN 14/08/202001/06/2018Language:

English

Version:

14/08/2020

File size:

8.3 MB

File name:

BA01867DEN_0220.pdf

-

-

-

Operating Instruction (BA)

Proline Promag P 500

Electromagnetic flowmeter

Modbus RS485EN 01/08/202214/08/202001/09/201915/12/201702/10/2017Language:

English

Version:

01/08/2022

File size:

9 MB

File name:

BA01402DEN_0622-00.pdf

-

-

-

Operating Instruction (BA)

Proline Promag P 500 FOUNDATION Fieldbus

Electromagnetic flowmeter

EN 14/08/202015/12/201701/11/2016Language:

English

Version:

14/08/2020

File size:

8.3 MB

File name:

BA01480DEN_0320.pdf

-

-

-

Operating Instruction (BA)

Proline Promag P 500

Electromagnetic flowmeter

HARTEN 01/08/202214/08/202001/09/201915/12/201702/10/2017Language:

English

Version:

01/08/2022

File size:

9.6 MB

File name:

BA01399DEN_0622-00.pdf

-

-

-

Operating Instruction (BA)

BA Proline Promag P 500

Electromagnetic flowmeter

PROFINET with Ethernet-APLEN 10/01/2024Language:

English

Version:

10/01/2024

File size:

9.3 MB

File name:

BA02102DEN_0122-00.pdf

-

-

-

Device Parameter (GP)

Proline Promag 500

Electromagnetic flowmeter

HARTEN 01/08/202201/09/201902/10/201702/08/2016Language:

English

Version:

01/08/2022

File size:

2.5 MB

File name:

GP01054DEN_0422-00.pdf

-

-

-

Device Parameter (GP)

Proline Promag 500

Electromagnetic flowmeter

Modbus RS485EN 01/08/202201/09/201902/10/201702/08/2016Language:

English

Version:

01/08/2022

File size:

3 MB

File name:

GP01055DEN_0422-00.pdf

-

-

-

Device Parameter (GP)

Proline Promag 500 PROFIBUS PA Description of Device Parameters

Electromagnetic flowmeter

EN 01/11/201802/08/2016Language:

English

Version:

01/11/2018

File size:

2 MB

File name:

GP01056DEN_0218.pdf

-

-

-

Device Parameter (GP)

Proline Promag 500 PROFINET Description of Device Parameters

Electromagnetic flowmeter

EN 15/07/201902/10/2017Language:

English

Version:

15/07/2019

File size:

2.1 MB

File name:

GP01119DEN_0219.pdf

-

-

-

Device Parameter (GP)

Proline Promag 500 EtherNet/IP Description of Device Parameters

Electromagnetic flowmeter

EN 02/10/2017Language:

English

Version:

02/10/2017

File size:

2 MB

File name:

GP01118DEN_0117.pdf

-

-

-

Device Parameter (GP)

Proline Promag 500 PROFIBUS DP Description of Device Parameters

Electromagnetic flowmeter

Proline Promag 500

PROFIBUS DPEN 01/06/2018Language:

English

Version:

01/06/2018

File size:

2.2 MB

File name:

GP01136DEN_0118.pdf

-

-

-

Device Parameter (GP)

Proline Promag 500 FOUNDATION Fieldbus Description of Device Parameters

Electromagnetic flowmeter

EN 01/11/2016Language:

English

Version:

01/11/2016

File size:

2.5 MB

File name:

GP01099DEN_0116.pdf

-

-

-

Device Parameter (GP)

GP Proline Promag 500

Electromagnetic flowmeter

PROFINET with Ethernet-APLEN 10/01/2024Language:

English

Version:

10/01/2024

File size:

2.2 MB

File name:

GP01169DEN_0122-00.pdf

-

-

-

Short Instruction (KA)

KA Flowmeter Proline 500 – digital

Transmitter with electromagnetic sensor

PROFINET with Ethernet-APLEN 10/01/2024Language:

English

Version:

10/01/2024

File size:

2.1 MB

File name:

KA01519DEN_0122-00.pdf

-

-

-

Short Instruction (KA)

Flowmeter Proline 500 Brief Operating Instructions

Transmitter with

electromagnetic sensorEN 01/02/201928/02/2017Language:

English

Version:

01/02/2019

File size:

2.1 MB

File name:

KA01293DEN_0219.pdf

-

-

-

Short Instruction (KA)

Flowmeter Proline 500 Brief Operating Instructions

Transmitter with electromagnetic sensor

EN 01/02/201901/06/2018Language:

English

Version:

01/02/2019

File size:

2.2 MB

File name:

KA01387DEN_0219.pdf

-

%20-%20CS01637X.jpg)