Overzicht specificaties

-

Accuracy

0.075% of individual sensor,

"PLATINUM" 0.05% of individual sensor -

Process temperature

–40...+125°C

(–40 ... +257°F) -

Pressure measuring range

400 mbar...10 bar

(6 psi...150 psi) -

Process pressure / max. overpressure limit

160 bar (2400 psi)

-

Main wetted parts

316L, Alloy C

-

Material process membrane

316L, AlloyC,

-

Measuring cell

400 mbar...10 bar

(6 psi...150psi)

Toepassingsgebied

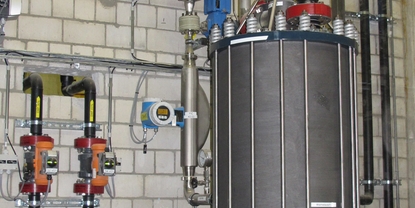

De elektronische drukverschilmeter Deltabar FMD72 is een drukverschilmeetsysteem dat wordt gebruikt om de druk, het niveau, het volume of de massa van vloeistoffen in drukvaten of distillatiekolommen/verdampers te meten. De hogedruksensor (HP) meet de hydrostatische druk. De lagedruksensor (LP) meet de topdruk. Het niveau wordt berekend in de transmitter aan de hand van deze twee digitale waarden. Het elektronische drukverschilmeetsysteem kent niet de problemen die bij de traditionele drukverschilmetingen voorkomen.

Voor het meten van het drukverschil, het niveau, het volume of de massa van vloeistoffen in drukvaten en distillatiekolommen/verdampers.

Procesaansluitingen: schroefdraad, flenzen en hygiënische koppelingen

Procestemperatuur: -40 tot +125 °C (-40 tot +257 °F), optioneel 250 °C (480 °F)

Meetbereik: 400 mbar tot +40 bar (6 tot 600 psi)

Nauwkeurigheid: enkele sensor tot ± 0,05%, systeem tot ± 0,07%

Internationale certificaten voor explosieveiligheid, hygiënische goedkeuringen

Voordelen

Elimineert traditionele mechanische problemen, wat een grotere procesbeschikbaarheid en -betrouwbaarheid tot gevolg heeft

Veiligheidsrisico's worden tot een minimum beperkt dankzij de architectuur en het ontwerp van het elektronische drukverschilmeetsysteem

Verlaging van total cost of ownership dankzij kortere installatietijd, minder onderhoud, minder productieonderbrekingen en minder reserveonderdelen

Multivariabele niveaumeting: HART-gebaseerd drukverschil, topdruk en sensortemperaturen van één systeem

Continue diagnose van het gehele systeem met HART-gebaseerde diagnostiek

Hoge reproduceerbaarheid en langetermijnstabiliteit

Procesveiligheid is gewaarborgd door kleine verzonken procesaansluitingen in hygiënische toepassingen

Video's

Extended selectie

-

High-end producten

- Functioneel en uiterst doelmatig

Technische topkwaliteit

Eenvoud

-

Eenvoudige producten

- Gemakkelijk te selecteren, installeren en gebruiken

Technische topkwaliteit

Eenvoud

-

Standaardproducten

- Betrouwbaar, robuust en onderhoudsarm

Technische topkwaliteit

Eenvoud

-

Gespecialiseerde producten

- Ontworpen voor veeleisende applicaties

Technische topkwaliteit

Eenvoud

Variabel

| FLEX selectie | Technische topkwaliteit | Eenvoud |

|---|---|---|

Fundamental selectie Voldoe aan uw basismeetvoorwaarden |

Technische topkwaliteit

|

Eenvoud

|

Lean selectie Beheers eenvoudig uw belangrijkste processen |

Technische topkwaliteit

|

Eenvoud

|

Extended selectie Optimaliseer uw processen met innovatieve technologieën |

Technische topkwaliteit

|

Eenvoud

|

Xpert selectie Beheers uw meest uitdagende applicaties |

Technische topkwaliteit

|

Eenvoud

Variabel |

Loading alternative products

Loading alternative products

-

-

EU-verklaring

Product family: Deltabar

Engelse versie - 11/2022

Product root: FMD71-, FMD72- Declaration number: EU_01048_01.22

EN NL 04/11/2022Taal:

Engels

Versie:

04/11/2022

Bestandsgrootte:

1.2 MB

Bestandsnaam:

EU_01048_01.22.pdf

-

-

-

Technische informatie (TI)

TI Deltabar FMD71, FMD72

Engelse versie - 04/2024

Level measurement with electronic differential pressure HART

EN NL 01/04/202406/10/202126/02/201808/06/201514/04/2014Taal:

Engels

Versie:

01/04/2024

Bestandsgrootte:

2.3 MB

Bestandsnaam:

TI01033PEN_0824-00.pdf

-

-

-

Technische informatie (TI)

TI Weld-in adapter, process adapter and flanges

Level, pressure and temperature measurement

EN NL 25/03/202415/09/202328/10/202130/07/202119/06/2020Taal:

Engels

Versie:

25/03/2024

Bestandsgrootte:

1.1 MB

Bestandsnaam:

TI00426FEN_2524.pdf

-

-

-

Technische informatie (TI)

TI Deltabar FMD71, FMD72

Level measurement with electronic differential pressure

HARTEN NL 01/04/202406/10/202126/02/201808/06/201514/04/2014Taal:

Engels

Versie:

01/04/2024

Bestandsgrootte:

2.3 MB

Bestandsnaam:

TI01033PEN_0824-00.pdf

-

-

-

Bedieningshandleiding (BA)

Deltabar FMD71, FMD72 Operating Instructions

Electronic differential pressure transmitter for level measurement

EN NL 26/02/201808/06/201514/04/201415/11/201301/08/2012Taal:

Engels

Versie:

26/02/2018

Bestandsgrootte:

3.4 MB

Bestandsnaam:

BA01044PEN_0617.pdf

-

-

-

Instrumentparameters (GP)

Deltabar FMD71, FMD72 Description of Device Parameters

Electronic differential pressure transmitter for level measurement

EN NL 26/02/201808/06/201514/04/201415/11/201301/08/2012Taal:

Engels

Versie:

26/02/2018

Bestandsgrootte:

711.1 KB

Bestandsnaam:

GP01013PEN_0617.pdf

-

-

-

Beknopte instructie (KA)

Cerabar S, Deltabar S, Deltapilot S - Exchange of the push buttons

Cerabar S, Deltabar S, Deltapilot S - Exchange of the push buttons

EN NL 17/05/2021Taal:

Engels

Versie:

17/05/2021

Bestandsgrootte:

396.6 KB

Bestandsnaam:

KA00610PA2_0312.pdf

-

-

-

Beknopte instructie (KA)

Deltabar FMD71, FMD72 Brief Operating Instructions

Electronic differential pressure transmitter for level measurement

EN NL 26/02/201808/06/201514/04/201423/10/201320/07/2012Taal:

Engels

Versie:

26/02/2018

Bestandsgrootte:

2 MB

Bestandsnaam:

KA01105PEN_0617.pdf

-

-

-

Beknopte instructie (KA)

Exchange of electronics on Cerabar S, Deltabar S, and Deltapilot S Austausch der Elektronik am Cerabar S, Deltabar S, Deltapilot S

Exchange of electronics on Cerabar S, Deltabar S, and Deltapilot S

FMB70-, FMD72-, FMD76-, FMD77-, FMD78-, PMC71-, PMD70-, PMD75-,

PMP71-, PMP72-, PMP75-EN NL 24/04/2012Taal:

Engels

Versie:

24/04/2012

Bestandsgrootte:

264.7 KB

Bestandsnaam:

KA678P-a2_0808.pdf

-

-

-

Beknopte instructie (KA)

Conversion instructions Cerabar S PMC/PMP7x and Deltabar S PMD/FMD7x from software version 1.x to software Version 2.x or higher

Conversion instructions Cerabar S PMC/PMP7x and Deltabar S

PMD/FMD7x from software version 1.x to software Version 2.x or higherEN NL 19/05/2021Taal:

Engels

Versie:

19/05/2021

Bestandsgrootte:

2.3 MB

Bestandsnaam:

KA00615PA2_0108.pdf

-

-

-

Montage-instructies (EA)

M12 plug for transmitter

Deltabar FMD71, FMD72

EN NL 05/03/2021Taal:

Engels

Versie:

05/03/2021

Bestandsgrootte:

1.2 MB

Bestandsnaam:

EA01356PEN_0121.pdf

-

-

-

Montage-instructies (EA)

M12 plug for sensor FMD71/72

Deltabar FMD71, FMD72

EN NL 05/03/2021Taal:

Engels

Versie:

05/03/2021

Bestandsgrootte:

536 KB

Bestandsnaam:

EA01358PEN_0121.pdf

-