Overzicht specificaties

-

Accuracy

Standard 0.1%

Platinum 0.075% -

Process temperature

-40°C...130°C

(-40°F...266°F) -

Pressure measuring range

1 bar...400 bar

(15 psi...6000 psi) -

Process pressure / max. overpressure limit

600 bar (9000 psi)

-

Main wetted parts

316L

-

Max. meetafstand

4000 m (13.123 ft) H2O

-

Material process membrane

316L, AlloyC,

Rhodium>Gold -

Measuring cell

400mbar...400bar

(5.8 psi...6000psi)

relative/ absolute

Toepassingsgebied

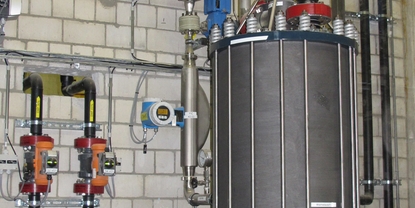

De digitale Cerabar PMP51-druktransmitter met metalen membraan wordt vooral gebruikt in de proces- en hygiëne-industrie voor druk-, niveau-, volume- of massameting in vloeistoffen en gassen. PMP51 is ontworpen voor hogedruktoepassingen tot 400 bar. Quick Setup met instelbaar meetbereik maakt een eenvoudige inbedrijfstelling mogelijk, verlaagt de kosten en bespaart tijd. SIL2 volgens IEC 61508 en IEC 61511.

Aluminium of roestvrijstalen (316L) behuizing met enkele kamer.

Procesaansluitingen: schroefdraad, flenzen of hygiënische koppelingen

Procestemperatuur: -40 tot +130 °C (-40 tot +266 °F), 150 °C (302 °F) gedurende 1 uur

Meetbereik: -1/0 tot +400 bar (-15/0 tot +6.000 psi)

Nauwkeurigheid: ± 0,1%, "Platina" ± 0,075%

Internationale certificaten voor explosieveiligheid, SIL, hygiënische goedkeuringen, maritieme goedkeuringen

Voordelen

Nauwkeurige metingen van de proceswaarde, zelfs wanneer de procestemperatuur verandert

Procesveiligheid is gewaarborgd door kleine verzonken procesaansluitingen in hygiënische toepassingen

Voor procesdrukbewaking tot SIL2, gecertificeerd volgens IEC 61508 en IEC 61511

Modulair concept voor eenvoudige vervanging van het display of de elektronica

Eenvoudige menugestuurde inbedrijfstelling via display, 4 tot 20 mA met HART, PROFIBUS PA, FOUNDATION Fieldbus

Naadloze en onafhankelijke systeemintegratie (HART/PA/FF)

Leverbaar met gemonteerd kranenblok: altijd passend, altijd getest op lekkages

Video's

Lean selectie

-

Standaardproducten

- Betrouwbaar, robuust en onderhoudsarm

Technische topkwaliteit

Eenvoud

-

Eenvoudige producten

- Gemakkelijk te selecteren, installeren en gebruiken

Technische topkwaliteit

Eenvoud

-

Standaardproducten

- Betrouwbaar, robuust en onderhoudsarm

Technische topkwaliteit

Eenvoud

-

Gespecialiseerde producten

- Ontworpen voor veeleisende applicaties

Technische topkwaliteit

Eenvoud

Variabel

| FLEX selectie | Technische topkwaliteit | Eenvoud |

|---|---|---|

Fundamental selectie Voldoe aan uw basismeetvoorwaarden |

Technische topkwaliteit

|

Eenvoud

|

Lean selectie Beheers eenvoudig uw belangrijkste processen |

Technische topkwaliteit

|

Eenvoud

|

Extended selectie Optimaliseer uw processen met innovatieve technologieën |

Technische topkwaliteit

|

Eenvoud

|

Xpert selectie Beheers uw meest uitdagende applicaties |

Technische topkwaliteit

|

Eenvoud

Variabel |

Loading alternative products

Loading alternative products

Voorganger

-

-

Technische informatie (TI)

TI Cerabar M PMC51, PMP51 , PMP55

Engelse versie - 04/2024

Process pressure measurement 4 to 20 mA, HART, IO-Link, PA, FF

EN NL 01/04/202422/08/202206/09/202101/04/202016/04/2019Taal:

Engels

Versie:

01/04/2024

Bestandsgrootte:

3.8 MB

Bestandsnaam:

TI00436PEN_3224-00.pdf

-

-

-

Technische informatie (TI)

TI Weld-in adapter, process adapter and flanges

Level, pressure and temperature measurement

EN NL 25/03/202415/09/202328/10/202130/07/202119/06/2020Taal:

Engels

Versie:

25/03/2024

Bestandsgrootte:

1.1 MB

Bestandsnaam:

TI00426FEN_2524.pdf

-

-

-

Technische informatie (TI)

TI Cerabar M PMC51, PMP51 , PMP55

Process pressure measurement

4 to 20 mA, HART, IO-Link, PA, FFEN NL 01/04/202422/08/202206/09/202101/04/202016/04/2019Taal:

Engels

Versie:

01/04/2024

Bestandsgrootte:

3.8 MB

Bestandsnaam:

TI00436PEN_3224-00.pdf

-

-

-

Bedieningshandleiding (BA)

Cerabar M PMC51, PMP51/55 Analog

With ceramic and silicon sensors

modular design and easy

operationEN NL 13/07/201610/12/201411/06/201417/08/201225/01/2012Taal:

Engels

Versie:

13/07/2016

Bestandsgrootte:

1.1 MB

Bestandsnaam:

BA00385PEN_2016.pdf

-

-

-

Bedieningshandleiding (BA)

Cerabar M /Deltabar M /Deltapilot M Operating Instructions PROFIBUS PA

Cerabar M PMC51, PMP51, PMP55, Pressure transmitter

Deltabar M

PMD55 Differential pressure transmitter Deltapilot M FMEN NL 13/07/201610/12/201411/06/201417/08/201225/01/2012Taal:

Engels

Versie:

13/07/2016

Bestandsgrootte:

7.8 MB

Bestandsnaam:

BA00383PEN_0816.pdf

-

-

-

Bedieningshandleiding (BA)

Cerabar M, Deltabar M, Deltapilot M HART (V 01.00.zz)

Cerabar M PMC51, PMP51/55 Pressure transmitter

Deltabar M

PMD55

Differential pressure transmitter

Deltapilot M FMB50/5EN NL 13/07/201610/12/201411/06/201417/08/201225/01/2012Taal:

Engels

Versie:

13/07/2016

Bestandsgrootte:

4.8 MB

Bestandsnaam:

BA00382PEN_2016.pdf

-

-

-

Bedieningshandleiding (BA)

Cerabar M / Deltabar M / Deltapilot M, Operating Instructions FOUNDATION Fieldbus

Cerabar M PMC51, PMP51, PMP55 Pressure transmitter

Deltabar M PMD55 Differential pressure transmitter

Deltapilot M FMB50 Hydrostatic pressure transmitterEN NL 13/07/201610/12/201411/06/201417/08/201225/01/2012Taal:

Engels

Versie:

13/07/2016

Bestandsgrootte:

7.8 MB

Bestandsnaam:

BA00384PEN_0816.pdf

-

-

-

Bedieningshandleiding (BA)

Cerabar M, Deltapilot M

Pressure / hydrostatics

IO-LinkEN NL 22/08/202231/07/2021Taal:

Engels

Versie:

22/08/2022

Bestandsgrootte:

1.7 MB

Bestandsnaam:

BA02136PEN_0222-00.pdf

-

-

-

Beknopte instructie (KA)

Cerabar M PMC51, PMP51, PMP55

Procesdrukmeting

FOUNDATION FieldbusEN NL 30/09/202113/07/201610/12/201411/06/201425/01/2012Taal:

Nederlands

Versie:

30/09/2021

Bestandsgrootte:

917.4 KB

Bestandsnaam:

KA01032PNL_0621-00.pdf

-

-

-

Beknopte instructie (KA)

Cerabar M PMC51, PMP51, PMP55

Procesdrukmeting

PROFIBUS PAEN NL 30/09/202113/07/201610/12/201411/06/201425/01/2012Taal:

Nederlands

Versie:

30/09/2021

Bestandsgrootte:

945.9 KB

Bestandsnaam:

KA01031PNL_0621-00.pdf

-

-

-

Beknopte instructie (KA)

Cerabar M PMC51, PMP51, PMP55

Procesdrukmeting

AnaloogEN NL 15/12/202113/07/201610/12/201411/06/201425/01/2012Taal:

Nederlands

Versie:

15/12/2021

Bestandsgrootte:

832.8 KB

Bestandsnaam:

KA01036PNL_1821-00.pdf

-

-

-

Beknopte instructie (KA)

Cerabar M PMC51, PMP51, PMP55

Procesdrukmeting

HARTEN NL 15/12/202110/12/201411/06/201425/01/201230/11/2010Taal:

Nederlands

Versie:

15/12/2021

Bestandsgrootte:

971.9 KB

Bestandsnaam:

KA01030PNL_1821-00.pdf

-

-

-

Beknopte instructie (KA)

Cerabar M PMC51, PMP51, PMP55

Procesdrukmeting

IO-LinkEN NL 22/08/202209/09/202101/07/2021Taal:

Nederlands

Versie:

22/08/2022

Bestandsgrootte:

1001.6 KB

Bestandsnaam:

KA01522PNL_0222-00.pdf

-

-

-

Montage-instructies (EA)

M12 plug, IO-Link

Deltapilot M FMB50

Cerabar M PMC51, PMP51, PMP55EN NL 23/11/2022Taal:

Engels

Versie:

23/11/2022

Bestandsgrootte:

730.3 KB

Bestandsnaam:

EA01457PEN_0122-00.pdf

-

-

-

Montage-instructies (EA)

Cable separate version Installation Instructions

Cerabar M, Cerabar S, Deltabar S, Deltapilot M, Deltapilot S

EN NL 31/01/2017Taal:

Engels

Versie:

31/01/2017

Bestandsgrootte:

324.7 KB

Bestandsnaam:

EA01192PA2_0117.pdf

-

-

-

Montage-instructies (EA)

Installation instruction - Ground terminal T14/T15/T17, F30/F31

Cerabar S, Deltabar S, Deltabar, Cerabar M, Deltabar M, Deltapilot M

EN NL 22/06/2015Taal:

Engels

Versie:

22/06/2015

Bestandsgrootte:

282.8 KB

Bestandsnaam:

EA01131PA2_0115.pdf

-

-

-

Montage-instructies (EA)

Electronics for Cerabar M, Deltapilot M Installation Instruction

CerabarM PMC51, PMP51, PMP55,

Deltapilot M FMB5xEN NL 30/09/201312/04/2012Taal:

Engels

Versie:

30/09/2013

Bestandsgrootte:

556.1 KB

Bestandsnaam:

EA00016PA2_1313.pdf

-

-

-

Montage-instructies (EA)

Harting plug HAN7D Installation instruction

Cerabar M/S, Deltabar M/S, Deltapilot M/S

EN NL 11/04/2012Taal:

Engels

Versie:

11/04/2012

Bestandsgrootte:

292.8 KB

Bestandsnaam:

EA0006PA2_0810.pdf

-

-

-

Montage-instructies (EA)

Sealing kit Installation Instruction

Cerabar

EN NL 08/08/201623/07/201507/04/2015Taal:

Engels

Versie:

08/08/2016

Bestandsgrootte:

205.3 KB

Bestandsnaam:

EA01128PA2_0316.pdf

-

-

-

Montage-instructies (EA)

Plug 3-pole, M12/M20 Installation instruction

Cerabar S, Deltabar S, Deltapilot S

EN NL 25/04/2012Taal:

Engels

Versie:

25/04/2012

Bestandsgrootte:

596.1 KB

Bestandsnaam:

EA00060PA2_0112.pdf

-

-

-

Montage-instructies (EA)

Display module VU340 Installation instruction

Cerabar M, Deltabar M, Deltapilot M

EN NL 12/04/2012Taal:

Engels

Versie:

12/04/2012

Bestandsgrootte:

233.2 KB

Bestandsnaam:

EA0015P-a2_0909.pdf

-