Over the past years, the cannabis industry has evolved into a multi-billion business. The range of cannabis-infused products, spanning beverages, snacks and medicine, is consistently expanding. As a result, the demand for cannabis extraction equipment has increased as well. Extracting the essential oil of the cannabis plant is a key step in the production process. The oil is then further processed and infused in different products. Instrumentation plays a crucial role along all process steps.

Belangrijke feiten

82.3 billion $

is the expected market value of the industrial cannabis market by end of 2027 https://www.marketsandmarkets.com/Market-Reports/cannabis-market-201768301.html

Cannabis processing

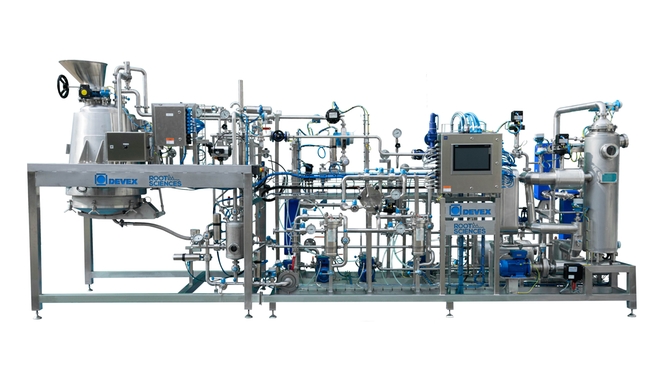

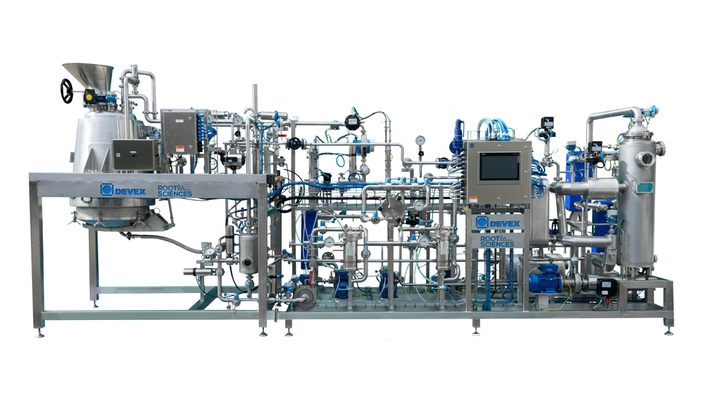

A DEVEX extraction system for the recovery of crude oil. This system extracts the active ingredients from cannabis with regard to the EU GMP guidelines enabled by Endress+Hauser instrumentation.

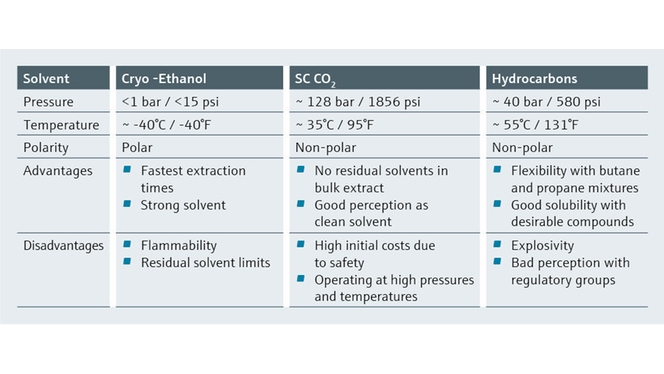

The process conditions for each cannabis extraction method.

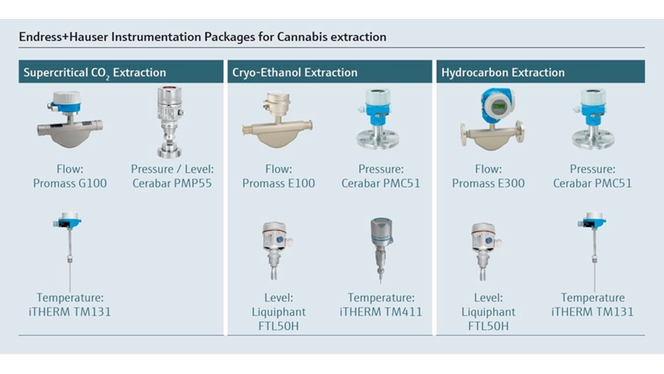

Endress+Hauser Instrumentation Packages for Cannabis extraction.

A DEVEX extraction system for the recovery of crude oil. This system extracts the active ingredients from cannabis with regard to the EU GMP guidelines enabled by Endress+Hauser instrumentation.

The process conditions for each cannabis extraction method.

Endress+Hauser Instrumentation Packages for Cannabis extraction.

Cannabis extraction under GMP guidelines

There are three different solvents that can be used to extract the desired compounds of the cannabis plant: ethanol, hydrocarbons and supercritical CO2. With different solvents come vastly different process conditions that impact the extracted cannabidiol oil or crude oil at the end of the extraction process. For example from -40 °C with ethanol to +55°C with hydrocarbon. Endress+Hauser has the right instrumentation to improve your extraction process with all three methods.

Our expertise in the field

Due to the significant impact on the product quality, the extraction process must be well-controlled. Our comprehensive instrumentation portfolio offers a wide range of technology to cover the entire extraction process, regardless of which specific method is applied. Our portfolio includes hygienic process connections and Ex certification as well as ceramic measuring cells.

- The pressure in pipes and vessels is monitored by

Winterization & Filtration process

The winterized cannabis oil then goes through a vacuum filtration process. This crucial step separates the majority of ethanol from the oil, allowing for its reuse within a closed-loop system. The winterization process eliminates fats, lipids, and other undesirable substances from the crude oil extract. This step is essential to enhance the purity of cannabinoids.

Our expertise in the field

Process conditions in this step can vary between -20°C and - 80°C for temperature and approximately 6 bar of pressure.

- Our

Distillation with cannabis extraction equipment

The final stage involves the distillation process, utilizing a thin-film evaporator to further refine and purify the cannabis oil. This step enables precise control over the cannabinoid profile of the end product.

Our expertise in the field

Accurate measurements of pressure, level and flow in this process step help control the key parameters that influence the separation and collection of the desired compounds.

- The pressure in pipes and vessels is monitored by

ATEX, FM/UL, FDA, hygienic requirements

ATEX, FM/UL, FDA, hygienic requirements as well as safety-related requirements are thoroughly implemented in our entire portfolio. Due to the use of ethanol as a solvent the cannabis extraction equipment is subject to explosion protection. Depending on the country of destination, the equipment is certified according to ATEX or for the North American market according to FM/UL standard.

Our expertise in the field

While GMP is not yet mandatory in these applications, all used Endress+Hauser devices posses the required approvals. To address customer concerns, our measuring devices have a hygienic design with FDA conformity for wetted parts. Factory calibration with certificates is the standard.

How we can help

Endress+Hauser offers a wide portfolio of technology and certifications that meets the requirements of the cannabis industry. Covering simple applications to high-temperature scenarios, from pressure sensors to conductivity measurements, as a sole provider we can deliver a comprehensive range of instrumentation. Numerous instruments come with ATEX and UL certification, coupled with hygienic process connections. Additionally, Endress+Hauser is a recognized brand in the life sciences industry.

- Accurate and reliable measuring of the process conditions for precision extraction

- Well-controlled extraction equipment to ensure product quality

- Precise temperature measurement to avoid the coextraction of unwanted by-products

- Precise flow measurement enables quantity-based recipe control to ensure consistent quality