Het gebruik van verouderde technologie kan een negatief effect hebben op zowel productieprocessen als beschikbaarheid. Oudere meettechnieken met mechanische componenten zijn minder nauwkeurig en vereisen meer onderhoud dan moderne equivalenten om de productie te waarborgen. Investeringen in het vervangen van oude mechanische instrumenten door innovatieve sensoren zullen zich uiteindelijk terugbetalen, zowel wat betreft de productiviteit als de besparingen op de onderhoudskosten.

Belangrijke feiten

250,000

US dollars lost

stopping your olefin process, when using outdated mechanical measurement technology, according to industry experts

Wat u kunt doen

Klik door deze procesoverzichten en leer hoe u de onderhoudskosten in uw chemische fabriek kunt verlagen!

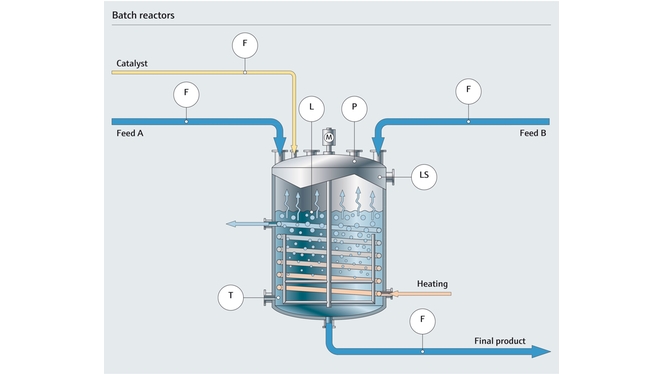

Met moderne technologieën houdt u uw polymerisatiereactor onder controle.

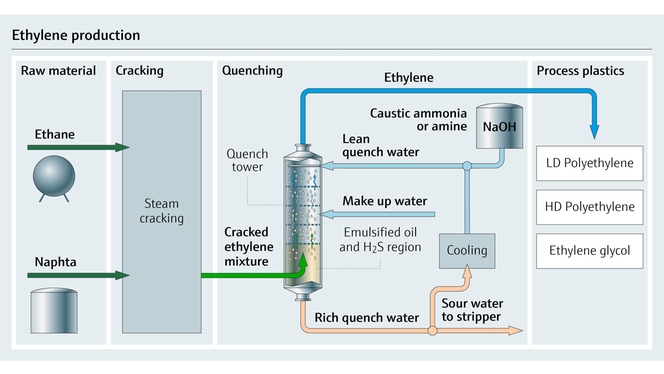

Het moderniseren van uw ethyleenproductie zorgt voor een soepel proces met betrouwbare gegevens om de productiviteit te verhogen en ongeplande stilstand te voorkomen.

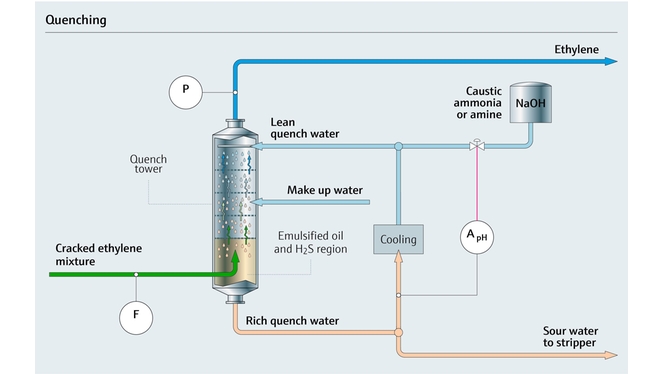

Voor een betrouwbare pH-meting van quenching-water op regelmatige tijdstippen moet de sensor ten minste om de dag wordt gereinigd, wat zeer tijds- en arbeidsintensief is.

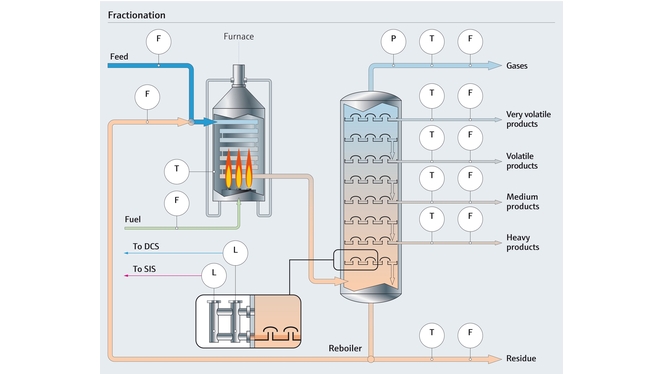

Een verminderde procesbewaking zorgt voor een onbetrouwbare fractionering – zo is er met de verouderde technologie voor niveaumeting geen bediening op afstand mogelijk.

Met moderne technologieën houdt u uw polymerisatiereactor onder controle.

Het moderniseren van uw ethyleenproductie zorgt voor een soepel proces met betrouwbare gegevens om de productiviteit te verhogen en ongeplande stilstand te voorkomen.

Voor een betrouwbare pH-meting van quenching-water op regelmatige tijdstippen moet de sensor ten minste om de dag wordt gereinigd, wat zeer tijds- en arbeidsintensief is.

Een verminderde procesbewaking zorgt voor een onbetrouwbare fractionering – zo is er met de verouderde technologie voor niveaumeting geen bediening op afstand mogelijk.

Meet polymerisatieviscositeit efficiënt

Viscositeit is een belangrijke vloeistofeigenschap en een fundamentele meetparameter in de polymerisatieprocesbewaking. Deze kan als een variabele worden gebruikt voor het bewaken van de productkwaliteit. Oudere viscositeitsmeetinstrumenten met mechanische componenten hebben regelmatig onderhoud nodig, om te waarborgen dat filters schoon blijven en de productie blijft draaien.

Onze ervaring in de praktijk

De Promass I coriolis-flowmeter van Endress+Hauser heeft meerdere voordelen ten opzichte van oudere mechanische instrumenten. Niet alleen levert hij betere prestaties, ook de operationele kosten zijn lager.

- Er is geen filter nodig, wat aanzienlijke tijd- en kostenbesparingen voor het onderhoud oplevert terwijl de procesprestaties en -veiligheid blijven bestaan

- Optimaliseer de productkwaliteit met een enkelvoudig meetpunt. Multivariabele inline-meting van flow, dichtheid, temperatuur en viscositeit

- Minimaliseer drukverliezen met een recht ontwerp met één buis

Verleng de levensduur van de sensor

Bij olefine-quenching kan een regelmatige pH-meting van het verontreinigde koelwater u helpen om verontreiniging onder in de toren te voorkomen. De sensoren moeten ten minste om de dag worden gereinigd, wat zeer tijds- en arbeidsintensief is. Als dit niet gebeurt, kan het zijn dat ze elke twee weken moeten worden vervangen.

Onze ervaring in de praktijk

De Liquiline CDC90 van Endress+Hauser verlengt de levensduur van uw sensor met meer dan het 30-voudige.

- Bespaar tijd met reiniging en kalibratie tijdens het proces zonder dat de elektroden verwijderd hoeven te worden

- Verhoog de efficiëntie met zelfdiagnostische systemen zoals sensortoestandscontroles

- Veiligheid voor mens en proces, doordat er geen omgang met verontreinigd water nodig is

Voorkom ongeplande onderbrekingen

Door het gebruik van oude, magnetische niveaumeters tijdens de olefine-fractionering in omgevingen met hoge temperaturen kan de veiligheid verminderen en kunnen onbetrouwbare metingen het gevolg zijn. Bovendien kunnen er ongeplande onderbrekingen optreden als de temperatuur te hoog wordt.

Onze ervaring in de praktijk

De Levelflex FMP51 geleide-golfradar van Endress+Hauser garandeert een gecontroleerde en betrouwbare fractionering.

- Meet niveaus op afstand, continu en betrouwbaar bij hoge temperaturen op basis van het Time-of-Flight-principe

- Voorkom ongeplande onderbrekingen door defecten te detecteren die een instrument kunnen blokkeren

- Verhoog de veiligheid met een tweede eenheid die is verbonden met het Safety Instrumented System (SIS)

Voordelen

Met meer dan 60 jaar toepassingskennis in de chemische industrie staan wij voor een langdurige relatie met onze klanten. Met uw voordelen in het achterhoofd helpen wij u om uw processen te optimaliseren, van de keuze van de juiste sensor tot en met onderhoudsconcepten. De basis voor uw succes zijn onze service- en verkoopteams in uw regio, die u graag terzijde staan.

Belangrijke feiten

13.000

medewerkers wereldwijd

Belangrijke feiten

Tot € 130.000

kostenbesparing per jaar bij het onderhoud van uw pH-elektrode als u gebruikmaakt van ons geautomatiseerde Liquiline reinigings- en kalibratiesysteem, uitgaande van 10 meetpunten in uw installatie

Belangrijke feiten

Meer dan 650.000

coriolis-flowmeters met succes geïnstalleerd

Hoe kunnen we helpen

Ongeacht het chemische proces of de chemische toepassing zal de nieuwste generatie sensoren van Endress+Hauser u helpen bij het bereiken van de productiviteits- en kostendoelen, wat resulteert in nauwkeurige metingen, minder noodzakelijke onderhoudsinspanningen en downtime tijdens kalibratie en proof-testen. Bovendien zijn onze verkoop- en serviceteams wereldwijd beschikbaar voor volledige ondersteuning, van het selecteren van de juiste sensoren, het vervangen van oude instrumenten tot het ontwerpen van klantspecifieke onderhoudsconcepten.

- Veilig in-proces-reiniging en kalibratie plus zelfdiagnose en moeiteloos proof-testen dankzij slimme instrumenten met geïntegreerde Heartbeat Technology

- Geavanceerde diagnostiek voor het voorkomen van ongeplande onderbrekingen

- Direct beschikbare mobiele procesgegevens met RFID-tags voor een snelle toegang tot de asset-informatie

- Uniforme platformen in transmitters voor het ondersteunen van een betrouwbare, gerichte onderhoudsaanpak

- De meest geschikte instrumenten met intrinsieke veiligheid en hoge nauwkeurigheid die betrouwbare gegevens en procesveiligheid bieden