Overzicht specificaties

-

Process temperature

-50 °C...+150 °C

(-58 °F...+302 °F) -

Process pressure / max. overpressure limit

Vacuum...64 bar

(Vacuum...928 psi) -

Min. density of medium

0.5g/cm³(0.4g/cm³ option)

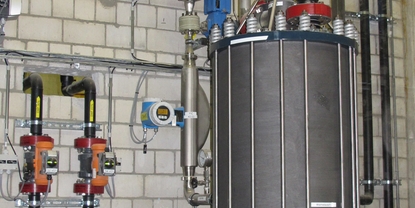

Toepassingsgebied

De Liquiphant FTL50 is een niveauschakelaar voor gebruik in gevaarlijke omgevingen en beschikt over alle internationale certificaten. Te gebruiken in alle sectoren. De FTL50 biedt functionele veiligheid SIL2/SIL3. De second line of defense garandeert de hoogste mate van veiligheid en beschikbaarheid van het instrument. Betrouwbare meetwaarden, niet beïnvloed door: veranderende mediumeigenschappen, stroming, turbulentie, gasbellen, schuim, trillingen of aangroei.

Niveauschakelaar voor alle vloeistoffen.

Procesaansluitingen: schroefdraad, flenzen en hygiënische koppeling (Tri-Clamp)

Temperatuur: -50 tot +150 °C (-58 tot +302 °F)

Druk: -1 tot +64 bar (-14,5 tot +928 psi)

Materiaal sensor: 316L, legering

Internationale certificaten voor explosieveiligheid, overvulbeveiliging (WHG), SIL, maritieme goedkeuringen

Voordelen

Gebruik in veiligheidssystemen die functionele veiligheid SIL2/SIL3 vereisen volgens

IEC 61508/IEC 61511-1Internationale certificaten voor explosieveiligheid en overvulbeveiliging (WHG)

Geen kalibratie nodig, eenvoudig op te starten

Geen mechanisch bewegende delen: geen onderhoud, geen slijtage, lange levensduur.

Vork wordt op beschadiging gecontroleerd: gegarandeerde werkingSecond line of defense ter bescherming van het milieu

Diverse gestandaardiseerde procesaansluitingen voor alle toepassingen

Sensor is gemaakt van roestvrij staal (316L) en een zeer corrosiebestendig materiaal (legering)

Video's

Extended selectie

-

High-end producten

- Functioneel en uiterst doelmatig

Technische topkwaliteit

Eenvoud

-

Eenvoudige producten

- Gemakkelijk te selecteren, installeren en gebruiken

Technische topkwaliteit

Eenvoud

-

Standaardproducten

- Betrouwbaar, robuust en onderhoudsarm

Technische topkwaliteit

Eenvoud

-

Gespecialiseerde producten

- Ontworpen voor veeleisende applicaties

Technische topkwaliteit

Eenvoud

Variabel

| FLEX selectie | Technische topkwaliteit | Eenvoud |

|---|---|---|

Fundamental selectie Voldoe aan uw basismeetvoorwaarden |

Technische topkwaliteit

|

Eenvoud

|

Lean selectie Beheers eenvoudig uw belangrijkste processen |

Technische topkwaliteit

|

Eenvoud

|

Extended selectie Optimaliseer uw processen met innovatieve technologieën |

Technische topkwaliteit

|

Eenvoud

|

Xpert selectie Beheers uw meest uitdagende applicaties |

Technische topkwaliteit

|

Eenvoud

Variabel |

Loading alternative products

Loading alternative products

Voorganger

-

-

Technische informatie (TI)

Liquiphant M FTL50, FTL51, FTL50H, FTL51H Technical Information

Engelse versie - 01/2020

Point level switch for all kinds of liquids

EN NL 10/01/202009/10/201730/11/201607/05/201504/04/2012Taal:

Engels

Versie:

10/01/2020

Bestandsgrootte:

2.7 MB

Bestandsnaam:

TI00328FEN_1820.pdf

-

-

-

Bedieningshandleiding (BA)

Liquiphant M/S FTL50, FTL51, FTL50H, FTL51H, FTL51C, FTL70, FTL71 Electronic insert FEL50A PA

Engelse versie - 08/2004

Vibration Limit Switch Level limit switch for all liquids. Suitable for use in hazardous areas, food and pharmaceuticals

EN NL 10/08/2004Taal:

Engels

Versie:

10/08/2004

Bestandsgrootte:

836 KB

Bestandsnaam:

BA141FEN.pdf

-

-

-

Technische informatie (TI)

TI Weld-in adapter, process adapter and flanges

Level, pressure and temperature measurement

EN NL 06/12/202425/03/202415/09/202328/10/202130/07/2021Taal:

Engels

Versie:

06/12/2024

Bestandsgrootte:

1.3 MB

Bestandsnaam:

TI00426FEN_2624.pdf

-

-

-

Technische informatie (TI)

Liquiphant M FTL50, FTL51, FTL50H, FTL51H Technical Information

Point level switch for all kinds of liquids

EN NL 10/01/202009/10/201730/11/201607/05/201504/04/2012Taal:

Engels

Versie:

10/01/2020

Bestandsgrootte:

2.7 MB

Bestandsnaam:

TI00328FEN_1820.pdf

-

-

-

Technische informatie (TI)

Liquiphant M FTL51C Technical Information

Point level switch for all kinds of liquids

with high corrosion-resistant coatingEN NL 31/08/201813/02/201719/05/201029/11/2007Taal:

Engels

Versie:

31/08/2018

Bestandsgrootte:

2 MB

Bestandsnaam:

TI00347FEN_1418.pdf

-

-

-

Technische informatie (TI)

Technical Information Liquiphant M Density and Density Computer FML621

Density computer for liquids

Also for use in hazardous areasEN NL 08/10/201212/02/200929/11/2007Taal:

Engels

Versie:

08/10/2012

Bestandsgrootte:

800.4 KB

Bestandsnaam:

TI00420FEN_1312.pdf

-

-

-

Bedieningshandleiding (BA)

Liquiphant M/S FTL50, FTL51, FTL50H, FTL51H, FTL51C, FTL70, FTL71 Electronic insert FEL50A PA

Vibration Limit Switch

Level limit switch for all liquids.

Suitable for use in hazardous areas, food and pharmaceuticalsEN NL 10/08/2004Taal:

Engels

Versie:

10/08/2004

Bestandsgrootte:

836 KB

Bestandsnaam:

BA141FEN.pdf

-

-

-

Beknopte instructie (KA)

Exchange of sensor on Liquiphant M/S

Exchange of sensor on Liquiphant M/S

EN NL 24/04/2012Taal:

Engels

Versie:

24/04/2012

Bestandsgrootte:

398.2 KB

Bestandsnaam:

KA00529FA2_0908.pdf

-

-

-

Beknopte instructie (KA)

Bedienungsanleitung/ Operating Instuction Liquiphant.

Sliding Sleeve

EN NL 01/05/200801/11/1998Taal:

Engels

Versie:

01/05/2008

Bestandsgrootte:

314.8 KB

Bestandsnaam:

KA100fa6_0308.pdf

-

-

-

Beknopte instructie (KA)

Liquiphant M Density FTL50, FTL51 Operating Instructions

Liquiphant M for density and concentration calculation

EN NL 29/06/201615/11/2007Taal:

Engels

Versie:

29/06/2016

Bestandsgrootte:

999.4 KB

Bestandsnaam:

KA00284FA6_1316.pdf

-

-

-

Beknopte instructie (KA)

FTL5x - sealing set

FTL5x - sealing set

EN NL 03/05/2021Taal:

Engels

Versie:

03/05/2021

Bestandsgrootte:

63.3 KB

Bestandsnaam:

KA00609F_A2.pdf

-

-

-

Beknopte instructie (KA)

Liquiphant M FTL50, FTL51 Operating Instructions

Point level switch for all kinds of liquids

EN NL 20/01/201729/06/201618/04/200601/04/2006Taal:

Engels

Versie:

20/01/2017

Bestandsgrootte:

982.5 KB

Bestandsnaam:

KA00143FA6_1417.pdf

-