©Endress+Hauser

Proline Promag L 400 voor de water- en afvalwaterindustrie

Opvolger

Veelzijdige standaardflowmeter voor de water- en afvalwaterindustrie

Meer informatie

Eenvoudige producten

Gemakkelijk te selecteren, installeren en gebruiken

Technische topkwaliteit

Eenvoud

Standaardproducten

Betrouwbaar, robuust en onderhoudsarm

Technische topkwaliteit

Eenvoud

High-end producten

Functioneel en uiterst doelmatig

Technische topkwaliteit

Eenvoud

Technische topkwaliteit

Eenvoud

FLEX selectie

Technische topkwaliteit

Eenvoud

Fundamental selectie

Voldoe aan uw basismeetvoorwaarden

Technische topkwaliteit

Eenvoud

Lean selectie

Beheers eenvoudig uw belangrijkste processen

Technische topkwaliteit

Eenvoud

Extended selectie

Optimaliseer uw processen met innovatieve technologieën

Technische topkwaliteit

Eenvoud

Xpert selectie

Beheers uw meest uitdagende applicaties

Technische topkwaliteit

Eenvoud

Product headline

std_productprofile_product_usp_8024.

Sensor features

std_productprofile_product_benefits_8026. Energy‐saving flow measurement – no pressure loss due to cross section constriction. Maintenance‐free – no moving parts.

Transmitter features

Safe operation – no need to open the device due to display with touch control, background lighting. Time‐saving local operation without additional software and hardware – integrated web server. Integrated verification – Heartbeat Technology.

Nominal diameter range

Lap joint flange, lap joint flange, stamped plate: DN 25 to 300 (1 to 12")

Wetted materials

Liner: PTFE; Polyurethane; Hard rubber

Measured variables

Volume flow, conductivity, mass flow

Max. meetfout

Volume flow (standard): ±0.5 % o.r. ± 1 mm/s (0.04 in/s)

Measuring range

9 dm³/min to 162 000 m³/h (2.5 gal/min to 1030 Mgal/d)

Medium temperature range

Liner material hard rubber: 0 to +80 °C (+32 to +176 °F)

Ambient temperature range

Flange material carbon steel: –10 to +60 °C (+14 to +140 °F)

Sensor housing material

DN 25 to 300 (1 to 12"): AlSi10Mg, coated

Transmitter housing material

Polycarbonat; AlSi10Mg, coated

Degree of protection

Compact version: IP66/67, type 4X enclosure

Display/Operation

4‐line backlit display with touch control (operation from outside)

Outputs

3 ouputs:

Digital communication

HART, PROFIBUS DP, EtherNet/IP, Modbus RS485

Power supply

AC 100 to 240 V / AC/DC 24 V

Metrological approvals and certificates

Calibration performed on accredited calibration facilities (acc. to ISO/IEC 17025), NAMUR

Hygienic approvals and certificates

Drinking water approval: ACS, KTW/W270, NSF 61, WRAS BS 6920

Meest gedownload

Proline Promag L 400

HART

Operating Instructions

Electromagnetic flowmeter

EN

NL

DE ES FR PL RU ZH

01/10/2017

14/03/2017

01/03/2015

05/06/2014

18/10/2013

Taal:

Engels

Versie:

01/10/2017

Bestandsgrootte:

6.7 MB

Bestandsnaam:

BA01062DEN_0617.pdf

Proline Promag L 400

PROFIBUS DP

Operating Instructions

Electromagnetic flowmeter

EN

NL

DE IT ZH

01/10/2017

01/03/2015

04/12/2014

05/06/2014

Taal:

Engels

Versie:

01/10/2017

Bestandsgrootte:

5.2 MB

Bestandsnaam:

BA01233DEN_0417.pdf

146 documenten

Proline Promag L 400

Technical Information

Electromagnetic flowmeter

EN

NL

Duits French Pools Russisch Chinees

01/10/2017

14/03/2017

14/03/2016

01/03/2015

04/12/2014

Taal:

Engels

Versie:

01/10/2017

Bestandsgrootte:

5 MB

Bestandsnaam:

TI01045DEN_0817.pdf

Proline Promag L 400

PROFIBUS DP

Operating Instructions

Electromagnetic flowmeter

EN

NL

Duits Italiaans Chinees

01/10/2017

01/03/2015

04/12/2014

05/06/2014

Taal:

Engels

Versie:

01/10/2017

Bestandsgrootte:

5.2 MB

Bestandsnaam:

BA01233DEN_0417.pdf

Proline Promag L 400

Modbus RS485

Operating Instructions

Electromagnetic flowmeter

EN

NL

Duits Russisch Chinees

01/10/2017

01/03/2015

04/12/2014

Taal:

Engels

Versie:

01/10/2017

Bestandsgrootte:

5.1 MB

Bestandsnaam:

BA01230DEN_0317.pdf

Proline Promag L 400

EtherNet/IP

Operating Instructions

Electromagnetic flowmeter

EN

NL

Duits Chinees

01/10/2017

01/03/2015

05/06/2014

18/10/2013

Taal:

Engels

Versie:

01/10/2017

Bestandsgrootte:

5.3 MB

Bestandsnaam:

BA01213DEN_0417.pdf

Proline Promag L 400

HART

Operating Instructions

Electromagnetic flowmeter

EN

NL

Duits Spaans French Pools Russisch Chinees

01/10/2017

14/03/2017

01/03/2015

05/06/2014

18/10/2013

Taal:

Engels

Versie:

01/10/2017

Bestandsgrootte:

6.7 MB

Bestandsnaam:

BA01062DEN_0617.pdf

Proline Promag 400

EtherNet/IP

Electromagnetic flowmeter

EN

NL

Duits

01/02/2022

23/12/2015

Taal:

Engels

Versie:

01/02/2022

Bestandsgrootte:

1.5 MB

Bestandsnaam:

GP01046DEN_0221-00.pdf

Electromagnetic flowmeter

EN

NL

Duits French Japans

01/09/2021

14/03/2017

07/12/2015

Taal:

Engels

Versie:

01/09/2021

Bestandsgrootte:

2 MB

Bestandsnaam:

GP01043DEN_0321.pdf

Proline Promag 400

PROFIBUS DP

Electromagnetic flowmeter

EN

NL

Duits

01/02/2022

23/12/2015

Taal:

Engels

Versie:

01/02/2022

Bestandsgrootte:

1.8 MB

Bestandsnaam:

GP01044DEN_0221-00.pdf

Proline Promag 400

Modbus RS485

Electromagnetic flowmeter

EN

NL

Duits

01/02/2022

23/12/2015

Taal:

Engels

Versie:

01/02/2022

Bestandsgrootte:

2 MB

Bestandsnaam:

GP01045DEN_0221-00.pdf

PROFIBUS DP transmitter

EN

NL

Bulgaars Tsjechisch Deens Duits Grieks Spaans Ests Fins French Kroatisch Hongaars Indonesisch Italiaans Japans Koreaans Lithuanian Latvian Noors Pools Portugees Roemeens Russisch Slovaaks Sloveens Zweeds Thais Turks Chinees

01/02/2022

01/02/2019

Taal:

Nederlands

Versie:

01/02/2022

Bestandsgrootte:

3.4 MB

Bestandsnaam:

KA01420DNL_0221-00.pdf

Proline Promag L 400

Brief Operating Instructions

Electromagnetic flowmeter

EN

NL

Tsjechisch Duits Spaans French Italiaans Portugees Zweeds Chinees

05/02/2018

10/09/2015

01/03/2015

04/12/2014

05/06/2014

Taal:

Engels

Versie:

05/02/2018

Bestandsgrootte:

1.6 MB

Bestandsnaam:

KA01113DEN_0718.pdf

Proline Promag

Beknopte handleiding

Proline Promag

EN

NL

Bulgaars Tsjechisch Deens Duits Grieks Spaans Ests Fins French Kroatisch Hongaars Indonesisch Italiaans Japans Koreaans Lithuanian Latvian Noors Pools Portugees Roemeens Russisch Slovaaks Sloveens Zweeds Thais Turks Chinees

01/04/2017

01/08/2016

01/12/2015

Taal:

Nederlands

Versie:

01/04/2017

Bestandsgrootte:

1.3 MB

Bestandsnaam:

KA01216DNL_0317.pdf

HART-transmitter

EN

NL

Bulgaars Tsjechisch Deens Duits Grieks Spaans Ests Fins French Kroatisch Hongaars Indonesisch Italiaans Japans Koreaans Lithuanian Latvian Noors Pools Portugees Roemeens Russisch Slovaaks Sloveens Zweeds Thais Turks Chinees

01/09/2021

01/02/2019

14/03/2017

Taal:

Nederlands

Versie:

01/09/2021

Bestandsgrootte:

4.4 MB

Bestandsnaam:

KA01263DNL_0321.pdf

EtherNet/IP transmitter

EN

NL

Bulgaars Tsjechisch Deens Duits Grieks Spaans Ests Fins French Kroatisch Hongaars Indonesisch Italiaans Japans Koreaans Lithuanian Latvian Noors Pools Portugees Roemeens Russisch Slovaaks Sloveens Zweeds Thais Turks Chinees

01/02/2022

01/02/2019

Taal:

Nederlands

Versie:

01/02/2022

Bestandsgrootte:

3.6 MB

Bestandsnaam:

KA01418DNL_0221-00.pdf

Modbus RS485 transmitter

EN

NL

Bulgaars Tsjechisch Deens Duits Grieks Spaans Ests Fins French Kroatisch Hongaars Indonesisch Italiaans Japans Koreaans Lithuanian Latvian Noors Pools Portugees Roemeens Russisch Slovaaks Sloveens Zweeds Thais Turks Chinees

01/02/2022

01/02/2019

Taal:

Nederlands

Versie:

01/02/2022

Bestandsgrootte:

3.4 MB

Bestandsnaam:

KA01419DNL_0221-00.pdf

Proline Promag L

Brief Operating Instructions

Proline Promag L

EN

NL

Duits Spaans Fins French Italiaans Portugees Russisch Chinees

12/02/2018

01/10/2017

14/03/2017

Taal:

Engels

Versie:

12/02/2018

Bestandsgrootte:

790.6 KB

Bestandsnaam:

KA01265DEN_0318.pdf

Proline 10, 400, 500, 500-digital, 800 Index B, 800 Index C, Cubemass

EN

NL

Duits

01/01/2024

15/12/2021

01/05/2021

01/04/2021

01/06/2020

Taal:

Engels

Versie:

01/01/2024

Bestandsgrootte:

1.2 MB

Bestandsnaam:

EA01024DA2_1223-00.pdf

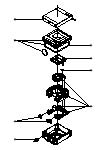

Replacing the O-ring sensor connector, profile seal for sensor

Promag 800 Index C, Promag 400 Index C

EN

NL

Duits

04/04/2022

15/03/2022

01/04/2021

Taal:

Engels

Versie:

04/04/2022

Bestandsgrootte:

2.7 MB

Bestandsnaam:

EA01325DA2_0322-00.pdf

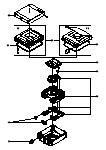

EA Replacing the Components for the Transmitter

Proline 400, 800 Index C, 500-digital

EN

NL

Duits

01/01/2024

15/12/2021

01/11/2021

01/04/2021

01/06/2020

Taal:

Engels

Versie:

01/01/2024

Bestandsgrootte:

2 MB

Bestandsnaam:

EA01094DA2_1223-00.pdf

Proline 10, 100, 400, 800 Index C, 500, 500-digital, CNG-, LNG-, LPGmass

EN

NL

Duits

01/01/2024

01/05/2021

01/04/2021

31/07/2020

02/08/2019

Taal:

Engels

Versie:

01/01/2024

Bestandsgrootte:

518.1 KB

Bestandsnaam:

EA01119DA2_0923-00.pdf

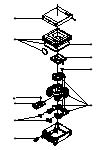

Zoek reservedelen op nummer in tekening

60 spare parts & accessories

60 spare parts & accessories

60 spare parts & accessories

Tekeningnummer

Bestelcode

45

71228789

Kit connec. board, D/L/W, remote,electr.

Tekeningnummer

Bestelcode

40

71228790

Electronic Promag 400 Index C

Tekeningnummer

Bestelcode

30

XPD0014-

Kit connec. board, L/W, remote, sensor

Tekeningnummer

Bestelcode

44

71228795

Tekeningnummer

Bestelcode

39

71185788

Electronic Promag 400 Index C update

Tekeningnummer

Bestelcode

30

XPD0040-

Display module, 4-draads, 400

Tekeningnummer

Bestelcode

50

XPD0017-

Kit cover, polycarbonate, 400(C), v1+v2

Tekeningnummer

Bestelcode

20

71443262

Kit deksel, alu, 400, 500 digitaal

Tekeningnummer

Bestelcode

20

71384170

Tekeningnummer

Bestelcode

24

71228796

Tekeningnummer

Bestelcode

24

71228796

Kit cover plastic, remote, Promag L/P/W

Tekeningnummer

Bestelcode

24

71188176

Kit 10 afdekdichtingen, polycarbonaat

Tekeningnummer

Bestelcode

25

71278077

Kit 10 dekseldicht. alu,400,500 digitaal

Tekeningnummer

Bestelcode

25

71278078

Kit cover gasket, plastic, Promag L/P/W

Tekeningnummer

Bestelcode

72

71188179

Kit housing gasket, D/L/W,compact,400(C)

Tekeningnummer

Bestelcode

71

71228793

Kit housing gaskets, remote, Alu

Tekeningnummer

Bestelcode

73

71228798

Kit housing gaskets, remote, Alu

Tekeningnummer

Bestelcode

73

71228798

Kit housing parts, D/L/W, compact,400(C)

Tekeningnummer

Bestelcode

12

71228794

Kit 10 wartels M20x1,5, D=5-12, FPM

Tekeningnummer

Bestelcode

15

71236702

Kit 10 wartels M20x1,5, D=5-12, FPM

Tekeningnummer

Bestelcode

15

71236702

PNG WARTEL M20 x 1,5 ( 10 STUKS )

Tekeningnummer

Bestelcode

17

50096840

Kit 10 ext. M20x1,5/G1/2", FVMQ

Tekeningnummer

Bestelcode

15

71236703

Kit 10 ext. M20x1,5/G1/2", FVMQ

Tekeningnummer

Bestelcode

15

71236703

Kit 10 ext. M20x1.5/G 1/2" (plug PVC)

Tekeningnummer

Bestelcode

17

50098041

Kit 10 ext. M20x1,5/NPT1/2", FVMQ

Tekeningnummer

Bestelcode

15

71236704

Kit 10 ext. M20x1,5/NPT1/2", FVMQ

Tekeningnummer

Bestelcode

15

71236704

Kit 10 ext. M20x1.5/NPT 1/2" (plug PVC)

Tekeningnummer

Bestelcode

17

50098042

Kit 10 wartels M20x1,5, D=5-12, FPM

Tekeningnummer

Bestelcode

15

71236702

Kit 10 cable glands M20x1,5, D=10-14,FPM

Tekeningnummer

Bestelcode

15

71236705

Kit 2 cable gland M20x1,5 reinf.Sensor

Tekeningnummer

Bestelcode

17

71029350

Kit 10 wartels M20x1,5, D=5-12, FPM

Tekeningnummer

Bestelcode

15

71236702

Kit 10 wartels M20x1,5, D=5-12, FPM

Tekeningnummer

Bestelcode

15

71236702

Kit plug M20x1,5/M12x1, EtherNet, FVMQ

Tekeningnummer

Bestelcode

15

71236706

Kit plug M20x1,5/M12x1, EtherNet, FVMQ

Tekeningnummer

Bestelcode

15

71236706

Kit 10 cable glands M20x1,5, D=10-14,FPM

Tekeningnummer

Bestelcode

15

71236705

Kit plug M20x1,5/M12x1, EtherNet, FVMQ

Tekeningnummer

Bestelcode

15

71236706

Kit plug M20x1,5/M12x1, EtherNet, FVMQ

Tekeningnummer

Bestelcode

15

71236706

Kit 10 ext. M20x1,5/G1/2", FVMQ

Tekeningnummer

Bestelcode

15

71236703

Kit 10 ext. M20x1,5/G1/2", FVMQ

Tekeningnummer

Bestelcode

15

71236703

Kit plug M20x1,5/M12x1, EtherNet, FVMQ

Tekeningnummer

Bestelcode

15

71236706

Kit plug M20x1,5/M12x1, EtherNet, FVMQ

Tekeningnummer

Bestelcode

15

71236706

Kit 10 ext. M20x1,5/NPT1/2", FVMQ

Tekeningnummer

Bestelcode

15

71236704

Kit 10 ext. M20x1,5/NPT1/2", FVMQ

Tekeningnummer

Bestelcode

15

71236704

Kit plug M20x1,5/M12x1, EtherNet, FVMQ

Tekeningnummer

Bestelcode

15

71236706

Kit plug M20x1,5/M12x1, EtherNet, FVMQ

Tekeningnummer

Bestelcode

15

71236706

Kit 10 ext. M20x1,5/NPT1/2", FVMQ

Tekeningnummer

Bestelcode

15

71236704

Kit 10 ext. M20x1,5/NPT1/2", FVMQ

Tekeningnummer

Bestelcode

15

71236704

Kit securing clamp, screw

Tekeningnummer

Bestelcode

13

71276494

Promag, kabel separate uitvoering

Promag, aardingsring/bescherm ring

Aardingskabelset, Promag L/W/P/S/E

Kit display bescherming,400,500 digitaal

Tekeningnummer

Bestelcode

82

71228792

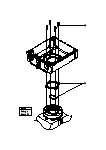

Transmitter/ ombouwkit Promag 400

Montage kit, transmitter Promag 400/800

Wij letten op uw privacy

We maken gebruik van cookies om uw browse-ervaring te verbeteren, statistische gegevens te verzamelen om de site-functionaliteit te optimaliseren en om reclame of content op maat te presenteren.

Door "Accepteer alles" te selecteren gaat u akkoord met ons gebruik van cookies.cookie-richtlijnen .

Aanpassen

Alleen het essentiële accepteren

Accepteer alles