%20Insertion%20version%20-%20PP01.jpg)

Overzicht specificaties

-

Max. meetfout

Gas: 1.0% o.r. (10 to 100% o.f.s.), 0.1% o.f.s. (1 to 10% o.f.s.)

-

Measuring range

20 to 733501 kg/h (44 to 1669340 lb/h)

-

Medium temperature range

-40 °C to +180°C (-40 °F to +356°F)

-

Max. process pressure

-0.5 to 20 bar_g (-7.25 to 290 psi_g)

-

Wetted materials

Materials for insertion tube

Stainless steel, 1.4404 (316/316L)

Process connections, process coupling

Stainless steel, 1.4404 (316/316L)

Sensing element

Unidirectional

Stainless steel, 1.4404 (316/316L)

Alloy C22, 2.4602 (UNS N06022);

Bidirectional

Stainless steel, 1.4404 (316/316L)

Reverse flow detection

Stainless steel, 1.4404 (316/316L)

Clamping rings

PEEK

PVDF

1.4404 (316/316L)

Flat ring seal

EPDM

FKM

Toepassingsgebied

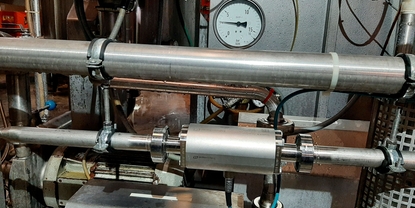

The patented sensor design of t-mass I provides unprecedented measurement stability in thermal insertion mass flow measurement. It compensates in real time for changes of process conditions: temperature, pressure, flow direction and gas type. The innovative remote transmitter of t-mass I 500 maximizes installation flexibility and operational safety in demanding environments. Heartbeat Technology enables measurement reliability and compliant verification.

Measuring principle is characterized by a high operable flow range and direct mass flow measurement

Measurement of utility and process gases and gas mixtures in circular piping or rectangular ducts

Device properties

Insertion version for DN 80 to 1500 (3 to 60")

Bidirectional measurement; high measuring performance

Patented drift-free sensor with SIL 2

Remote version with up to 4 I/Os

Backlit display with touch control and WLAN access

Standard cable between sensor and transmitter

Voordelen

Flexible, convenient programming based on 21 standard gases or freely definable gas mixtures thereof

High level of process control – premium measurement accuracy and repeatability

Reliable monitoring – detection of process disturbances and reverse flow

Flexible installation – suitable for large dimensional range and circular pipes or rectangular ducts

Full access to process and diagnostic information – numerous, freely combinable I/Os and fieldbuses

Reduced complexity and variety – freely configurable I/O functionality

Integrated verification – Heartbeat Technology

Video's

Extended selectie

-

High-end producten

- Functioneel en uiterst doelmatig

Technische topkwaliteit

Eenvoud

-

Eenvoudige producten

- Gemakkelijk te selecteren, installeren en gebruiken

Technische topkwaliteit

Eenvoud

-

Standaardproducten

- Betrouwbaar, robuust en onderhoudsarm

Technische topkwaliteit

Eenvoud

-

Gespecialiseerde producten

- Ontworpen voor veeleisende applicaties

Technische topkwaliteit

Eenvoud

Variabel

| FLEX selectie | Technische topkwaliteit | Eenvoud |

|---|---|---|

Fundamental selectie Voldoe aan uw basismeetvoorwaarden |

Technische topkwaliteit

|

Eenvoud

|

Lean selectie Beheers eenvoudig uw belangrijkste processen |

Technische topkwaliteit

|

Eenvoud

|

Extended selectie Optimaliseer uw processen met innovatieve technologieën |

Technische topkwaliteit

|

Eenvoud

|

Xpert selectie Beheers uw meest uitdagende applicaties |

Technische topkwaliteit

|

Eenvoud

Variabel |

Loading alternative products

Loading alternative products

Voorganger

-

-

Ex-veiligheidsinstructie (XA)

XA Proline t-mass 500

Engelse versie - 03/2024

ATEX: II1/2G II2D IECEx: Zone 0/1 Zone 21

EN NL 01/03/202417/09/2020Taal:

Engels

Versie:

01/03/2024

Bestandsgrootte:

608.3 KB

Bestandsnaam:

XA01970DEN_0224-00.pdf

-

-

-

Technische informatie (TI)

TI Proline t-mass I 500

Engelse versie - 07/2023

Thermal mass flowmeter

EN NL 28/07/202305/07/202117/09/2020Taal:

Engels

Versie:

28/07/2023

Bestandsgrootte:

5.5 MB

Bestandsnaam:

TI01503DEN_0323-00.pdf

-

-

-

Technische informatie (TI)

TI Proline t-mass I 500

Thermal mass flowmeter

EN NL 28/07/202305/07/202117/09/2020Taal:

Engels

Versie:

28/07/2023

Bestandsgrootte:

5.5 MB

Bestandsnaam:

TI01503DEN_0323-00.pdf

-

-

-

Bedieningshandleiding (BA)

BA Proline t-mass I 500

Thermal mass flowmeter

HARTEN NL 28/07/202305/07/202117/09/2020Taal:

Engels

Versie:

28/07/2023

Bestandsgrootte:

7.4 MB

Bestandsnaam:

BA01997DEN_0323-00.pdf

-

-

-

Bedieningshandleiding (BA)

BA Proline t-mass I 500

Thermal mass flowmeter

Modbus RS485EN NL 28/07/202305/07/202117/09/2020Taal:

Engels

Versie:

28/07/2023

Bestandsgrootte:

6.7 MB

Bestandsnaam:

BA01999DEN_0323-00.pdf

-

-

-

Instrumentparameters (GP)

GP Proline t-mass 500 Modbus RS485

Thermal mass flowmeter

EN NL 15/03/202401/07/202117/09/2020Taal:

Engels

Versie:

15/03/2024

Bestandsgrootte:

2.5 MB

Bestandsnaam:

GP01146DEN_0324-00.pdf

-

-

-

Instrumentparameters (GP)

Proline t-mass 500 HART

Thermal mass flowmeter

EN NL 01/07/202117/09/2020Taal:

Engels

Versie:

01/07/2021

Bestandsgrootte:

2.1 MB

Bestandsnaam:

GP01145DEN_0221.pdf

-

-

-

Beknopte instructie (KA)

Proline t-mass I

Thermische massaflowsensor

EN NL 05/07/202101/07/202117/09/2020Taal:

Nederlands

Versie:

01/07/2021

Bestandsgrootte:

1 MB

Bestandsnaam:

KA01443DNL_0221-00.pdf

-

-

-

Beknopte instructie (KA)

Proline 500 – digital HART

Transmitter met thermische massaflowsensor

EN NL 05/07/202101/07/202117/09/2020Taal:

Nederlands

Versie:

01/07/2021

Bestandsgrootte:

1.4 MB

Bestandsnaam:

KA01446DNL_0221-00.pdf

-

-

-

Beknopte instructie (KA)

Proline 500 – digitaal Modbus RS485

Transmitter met thermische massaflowsensor

EN NL 05/07/202101/07/202117/09/2020Taal:

Nederlands

Versie:

01/07/2021

Bestandsgrootte:

1.7 MB

Bestandsnaam:

KA01447DNL_0221-00.pdf

-

-

-

Montage-instructies (EA)

EA Replacing Small Parts

Proline 10, 400, 500, 500-digital, 800 Index B, 800 Index C, Cubemass

EN NL 01/01/202415/12/202101/05/202101/04/202101/06/2020Taal:

Engels

Versie:

01/01/2024

Bestandsgrootte:

1.2 MB

Bestandsnaam:

EA01024DA2_1223-00.pdf

-

-

-

Montage-instructies (EA)

EA Replacing the Components for the Transmitter

Proline 400, 800 Index C, 500-digital

EN NL 01/01/202415/12/202101/11/202101/04/202101/06/2020Taal:

Engels

Versie:

01/01/2024

Bestandsgrootte:

2 MB

Bestandsnaam:

EA01094DA2_1223-00.pdf

-

-

-

Montage-instructies (EA)

Hot tap

t-mass I 300, 500-digital

EN NL 01/07/202131/07/2020Taal:

Engels

Versie:

01/07/2021

Bestandsgrootte:

1.8 MB

Bestandsnaam:

EA01288DA2_0221.pdf

-

-

-

Montage-instructies (EA)

EA Alteration Display module to Display module with WLAN

Proline 300, 400, 500, 500-digital

EN NL 01/01/202401/08/202131/07/202002/08/201902/01/2019Taal:

Engels

Versie:

01/01/2024

Bestandsgrootte:

1.4 MB

Bestandsnaam:

EA01158DA2_0823-00.pdf

-

-

-

Montage-instructies (EA)

EA Replacing Small parts

Proline 10, 100, 400, 800 Index C, 500, 500-digital, CNG-, LNG-, LPGmass

EN NL 01/01/202401/05/202101/04/202131/07/202002/08/2019Taal:

Engels

Versie:

01/01/2024

Bestandsgrootte:

518.1 KB

Bestandsnaam:

EA01119DA2_0923-00.pdf

-

-

-

Montage-instructies (EA)

EA Replacing the Display Protection

Proline 400, 800 Index C, 500-digital

EN NL 01/01/202415/12/202101/06/202002/08/201901/03/2018Taal:

Engels

Versie:

01/01/2024

Bestandsgrootte:

480 KB

Bestandsnaam:

EA01093DA2_0723-00.pdf

-

-

-

Montage-instructies (EA)

EA Replacing the electronics

Proline 300, 500, 500-digital

EN NL 01/01/202401/07/202301/06/202131/07/202002/08/2019Taal:

Engels

Versie:

01/01/2024

Bestandsgrootte:

1.6 MB

Bestandsnaam:

EA01145DA2_0823-00.pdf

-

-

-

Montage-instructies (EA)

EA Protective Cover connection compartment

Proline 300, 500, 500-digital

EN NL 01/01/202401/06/202301/06/202131/07/202002/08/2019Taal:

Engels

Versie:

01/01/2024

Bestandsgrootte:

6.2 MB

Bestandsnaam:

EA01146DA2_0823-00.pdf

-

-

-

Montage-instructies (EA)

EA Pipe mounting set

Proline 400, 500-digital

EN NL 01/01/202415/12/202131/07/202002/08/201901/02/2017Taal:

Engels

Versie:

01/01/2024

Bestandsgrootte:

518.8 KB

Bestandsnaam:

EA01195DA2_0523-00.pdf

-

-

-

Montage-instructies (EA)

EA Replacing the display module

Proline 300, 500, 500-digital, DKX001–

EN NL 01/01/202401/06/202131/07/202002/08/201902/01/2019Taal:

Engels

Versie:

01/01/2024

Bestandsgrootte:

712.8 KB

Bestandsnaam:

EA01144DA2_0723-00.pdf

-

-

-

Montage-instructies (EA)

Replacing the Sensor

t-mass I, F 500-digital

EN NL 31/07/2020Taal:

Engels

Versie:

31/07/2020

Bestandsgrootte:

520.1 KB

Bestandsnaam:

EA01285DA2_0120.pdf

-

-

-

Montage-instructies (EA)

Replacing the transmitter

t-mass 500-digital

EN NL 31/07/2020Taal:

Engels

Versie:

31/07/2020

Bestandsgrootte:

304.3 KB

Bestandsnaam:

EA01287DA2_0120.pdf

-

%20Insertion%20version%20-%20PP01.jpg)

%20-%20CS01637X.jpg)

.jpg)