Overzicht specificaties

-

Accuracy

Rod probe :+/- 2 mm (0.08 in)

Rope probe <= 15 m (49 ft):

+/- 2 mm (0.08 in)

Rope probe > 15 m (49 ft):

+/- 10 mm (0.39 in) -

Process temperature

-50...+200 °C

(-58...+392 °F) -

Process pressure / max. overpressure limit

Vacuum...40 bar

(Vacuum...580 psi) -

Max. meetafstand

Rod:

4 m (13 ft) Min DK>1.6

Rope:

25 m...30 m (82 ft...98 ft) Min DK>1.6;

30 m...45 m (98 ft...148 ft) Min DK>1,9 -

Main wetted parts

Rod probe:

304, 304L, 316L, PTFE, PFA

Rope probe:

304, 304L, 316, 316L, PTFE, PFA

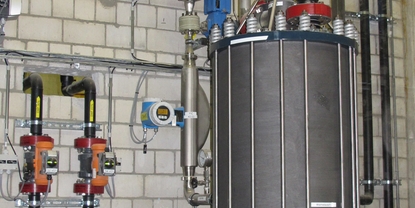

Toepassingsgebied

Levelflex FMP52 voor niveaumetingen in agressieve vloeistoffen met chemisch bestendige gesloten sonde met PTFE-coating. Alle natte onderdelen zijn van FDA-toegelaten materialen. De FMP52 geleide radar biedt maximale betrouwbaarheid zelfs bij bewegende oppervlakken. De Levelflex FMP52 wordt gebruikt voor continue niveaumetingen in vloeistoffen, pasta's en slurries, maar ook voor interfacemetingen. De meting wordt niet beïnvloed door veranderende media, temperatuurschommelingen, inerte gassen of dampen.

Versie met staaf- of kabelsonde.

Procesaansluitingen: flens- of procesaansluitingen voor hygiënevoorschriften (Tri-Clamp, 11851)

Temperatuur: -50 tot +200 °C (-58 tot +392 °F)

Druk: -1 tot +40 bar (-14,5 tot +580 psi)

Meetbereik max.: staaf 4 m (13 ft), kabel 45 m (148 ft)

Nauwkeurigheid: staafsonde ± 2 mm (0,08")

Internationale certificaten voor explosieveiligheid, overvulbeveiliging WHG, SIL, hygiënecertificaten, maritieme goedkeuring, 5-punts lineariteitsprotocol

Voordelen

Betrouwbare meting zelfs bij veranderende product- en procesomstandigheden

HistoROM-datamanagementconcept voor snelle en eenvoudige inbedrijfstelling, onderhoud en diagnostiek

Optimale betrouwbaarheid dankzij de multi-echotracking-evaluatie

Hardware en software ontwikkeld volgens IEC 61508 tot SIL3

Heartbeat Technology voor een kostenefficiënte en veilige werking van de installatie gedurende de gehele levenscyclus

Naadloze integratie in regel- of bedrijfsmiddelen-managementsystemen en intuïtief, menugestuurd bedieningsconcept (ter plaatse of via het bedieningssysteem)

De eenvoudigste proof test ter wereld voor SIL en WHG bespaart tijd en geld

Video's

Extended selectie

-

High-end producten

- Functioneel en uiterst doelmatig

Technische topkwaliteit

Eenvoud

-

Eenvoudige producten

- Gemakkelijk te selecteren, installeren en gebruiken

Technische topkwaliteit

Eenvoud

-

Standaardproducten

- Betrouwbaar, robuust en onderhoudsarm

Technische topkwaliteit

Eenvoud

-

Gespecialiseerde producten

- Ontworpen voor veeleisende applicaties

Technische topkwaliteit

Eenvoud

Variabel

| FLEX selectie | Technische topkwaliteit | Eenvoud |

|---|---|---|

Fundamental selectie Voldoe aan uw basismeetvoorwaarden |

Technische topkwaliteit

|

Eenvoud

|

Lean selectie Beheers eenvoudig uw belangrijkste processen |

Technische topkwaliteit

|

Eenvoud

|

Extended selectie Optimaliseer uw processen met innovatieve technologieën |

Technische topkwaliteit

|

Eenvoud

|

Xpert selectie Beheers uw meest uitdagende applicaties |

Technische topkwaliteit

|

Eenvoud

Variabel |

Loading alternative products

Loading alternative products

Voorganger

-

-

Technische informatie (TI)

TI Levelflex FMP51, FMP52, FMP54

Engelse versie - 04/2025

Guided-wave radar

EN NL 25/04/202501/10/202422/02/202312/04/202231/07/2020Taal:

Engels

Versie:

25/04/2025

Bestandsgrootte:

5 MB

Bestandsnaam:

TI01001FEN_3225-00.pdf

-

-

-

Technische informatie (TI)

TI Weld-in adapter, process adapter and flanges

Engelse versie - 12/2024

Level, pressure and temperature measurement

EN NL 06/12/202425/03/202415/09/202328/10/202130/07/2021Taal:

Engels

Versie:

06/12/2024

Bestandsgrootte:

1.3 MB

Bestandsnaam:

TI00426FEN_2624.pdf

-

-

-

Technische informatie (TI)

TI Weld-in adapter, process adapter and flanges

Level, pressure and temperature measurement

EN NL 06/12/202425/03/202415/09/202328/10/202130/07/2021Taal:

Engels

Versie:

06/12/2024

Bestandsgrootte:

1.3 MB

Bestandsnaam:

TI00426FEN_2624.pdf

-

-

-

Technische informatie (TI)

TI Levelflex FMP51, FMP52, FMP54

Guided-wave radar

EN NL 25/04/202501/10/202422/02/202312/04/202231/07/2020Taal:

Engels

Versie:

25/04/2025

Bestandsgrootte:

5 MB

Bestandsnaam:

TI01001FEN_3225-00.pdf

-

-

-

Bedieningshandleiding (BA)

BA Levelflex FMP51, FMP52, FMP54 PROFIBUS PA

Guided-wave radar

EN NL 01/10/202421/02/202330/06/202212/04/201816/11/2017Taal:

Engels

Versie:

01/10/2024

Bestandsgrootte:

4.9 MB

Bestandsnaam:

BA01006FEN_2124-00.pdf

-

-

-

Bedieningshandleiding (BA)

Levelflex / Levelflex M Zentrierscheibe / Centering disk (PFA) Mounting Instructions

Accessory

EN NL 29/09/201727/02/201425/04/201208/02/201124/09/2010Taal:

Engels

Versie:

29/09/2017

Bestandsgrootte:

82.6 KB

Bestandsnaam:

BA00378FA2_1717.pdf

-

-

-

Bedieningshandleiding (BA)

Levelflex FMP51, FMP52, FMP54 HART Inbedrijfstellingsvoorschrift

Geleide radar niveaumeting

EN NL 01/10/202413/12/202230/06/202231/07/202012/04/2018Taal:

Nederlands

Versie:

15/12/2016

Bestandsgrootte:

5.6 MB

Bestandsnaam:

BA01001FNL_1916.pdf

-

-

-

Bedieningshandleiding (BA)

BA Levelflex FMP51, FMP52, FMP54 FOUNDATION Fieldbus

Guided-wave radar

EN NL 01/10/202421/02/202330/06/202212/04/201816/11/2017Taal:

Engels

Versie:

01/10/2024

Bestandsgrootte:

6.1 MB

Bestandsnaam:

BA01052FEN_0924-00.pdf

-

-

-

Instrumentparameters (GP)

Levelflex FMP5x HART Description of Device Parameters

Guided wave radar

EN NL 28/04/201630/10/201426/02/201429/07/201101/10/2010Taal:

Engels

Versie:

28/04/2016

Bestandsgrootte:

3.3 MB

Bestandsnaam:

GP01000FEN_1616.pdf

-

-

-

Instrumentparameters (GP)

Levelflex FMP50, FMP51, FMP52, FMP53, FMP54, FMP55, FMP56, FMP57 PROFIBUS PA Description of Device Parameters

Guided wave radar

EN NL 30/10/201404/08/2011Taal:

Engels

Versie:

30/10/2014

Bestandsgrootte:

4.7 MB

Bestandsnaam:

GP01001FEN_1314.pdf

-

-

-

Instrumentparameters (GP)

Levelflex FMP50, FMP51, FMP52, FMP53, FMP54, FMP55, FMP56, FMP57 FOUNDATION Fieldbus Description of Device Parameters

Guided wave radar

EN NL 09/06/201527/04/2012Taal:

Engels

Versie:

09/06/2015

Bestandsgrootte:

3.5 MB

Bestandsnaam:

GP01015FEN_0215.pdf

-

-

-

Beknopte instructie (KA)

Levelflex FMP51, FMP52, FMP54 HART

Geleide radar niveaumeting

EN NL 30/06/202205/04/202212/04/201817/11/201712/02/2015Taal:

Nederlands

Versie:

05/04/2022

Bestandsgrootte:

1.5 MB

Bestandsnaam:

KA01077FNL_1922-00.pdf

-