Aeration in wastewater treatment accounts for approximately 60% of the total energy consumption in wastewater treatment plants. Energy consumption is the main cost driver in wastewater treatment, and its optimization is one if the many challenges faced by plant operators also having to meet ever more demanding safety legislation. Our online oxygen and nutrient measurement solutions not only drive energy savings in aeration control, they enable demonstrable improvements in biological processes.

Key facts

Up to 30%

of the energy costs

in a wastewater treatment plant can be saved by using our solution for aeration control.

Discover the aeration process in wastewater treatment

Simplified aeration monitoring

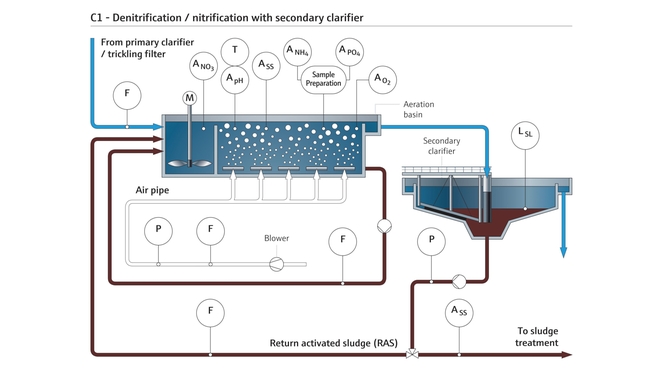

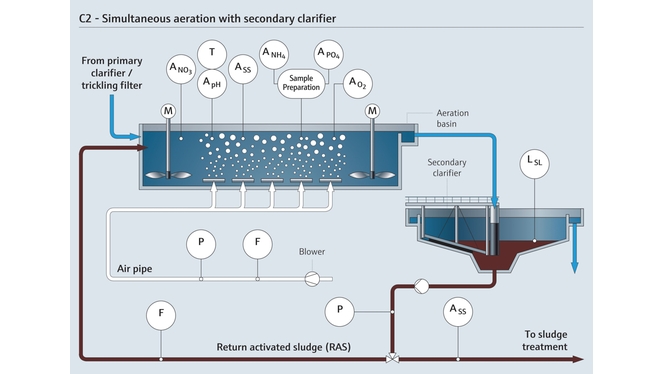

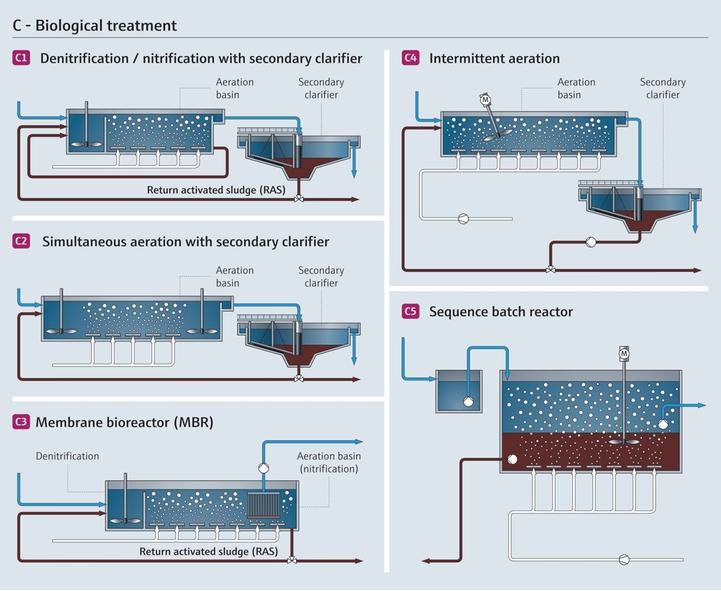

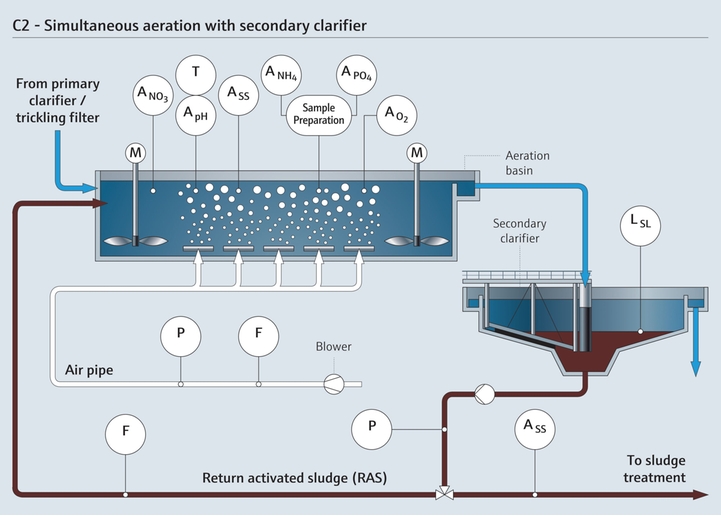

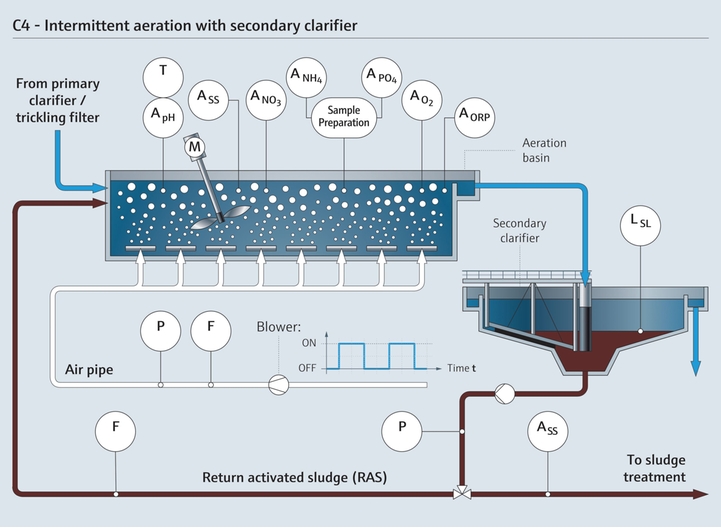

Reliable aeration requires the accurate monitoring of the multiple environmental parameters necessary for optimal bacteriological processes, such as oxygen, ammonium, nitrate, pH, temperature and suspended solids. Such monitoring increases greatly the complexity of management of the modern wastewater treatment plant.

Our expertise in the field

Our extensive portfolio of instruments, services and solution help to optimize the aeration process, enabling reliable and efficient plant management.

- Discover our portfolio of liquid analysis sensor covering all important parameters

- Take a closer look on our thermometers and transmitters from temperature measurement

- Manage up to 8 measuring points of similar or different parameters with our multichannel transmitter Liquiline CM448. Open communication interfaces sustain system integration, smooth operations and effortless maintenance and calibration

- Safely remove nitrogen from wastewater with Liquiline Control

Reduced ammonium levels

The first step in nitrogen removal is nitrification. This requires close monitoring of the degradation of ammonium and represents a significant cost factor, as this type of liquid analysis often requires the addition of further substances to enable measurements.

Our expertise in the field

Our reliable, easy to use and durable technologies for measuring ammonium concentration throughout nitrification enable the operator to react early to ammonium level disturbances.

- Integration of reliable sensors such as our digital ammonium and nitrate Memosens sensor ISEmax CAS40D to optimize the treatment process

- Rely on high-precision ammonium measurement in all critical control points using Liquiline System CA80AM

- Further optimized life cycle costs due to lower maintenance and fewer consumables in treatment processes

Flexible, accurate oxygen control

Monitoring and sustaining the oxygen levels vital for a reliable aeration process can lead to significant energy costs for the wastewater treatment plant. Plant operators rely on fast response times and low maintenance of equipment.

Our expertise in the field

Oxygen levels are controlled by comparing the measured concentration and the set-point. Our oxygen monitoring solutions can be flexibly adapted to your requirements, delivering reliable and accurate results rapidly.

- Measure dissolved oxygen concentration accurate with our digital aperometric oxygen sensor COS51Eor digital optical oxygen sensor Oxymax COS61D

- Increase process safety with Memosens 2.0 digital technology sensors

- Reduced energy consumption by further optimizing the blower usage

Benefits

Working together with numerous customers, our industry and application experts have achieved striking results in optimizing the aeration process in wastewater treatment plants. The complete portfolio from Endress+Hauser in regards of instrumentation, services and solutions guarantees success from the very start. Our goal is to be a reliable partner in every aspect of wastewater treatment.

Key facts

Up to 30%

of the energy costs at most can be saved using our solution for aeration control

Key facts

40%

longer lifetime of analytical sensors with Memosens technology

Key facts

300,000

Memosens sensors installed worldwide

How we can help

Our advanced monitoring solutions enable optimal control of the aeration process, reducing energy and chemicals consumption whilst continuing to satisfy all current legislation.

- Advanced monitoring of environmental parameters for reliable bacteriological processes

- Improved nitrification process control for reduced ammonium usage

- Precise oxygen measurement for optimal energy consumption of the blower