Endress+Hauser Conducta GmbH+Co. KG

Endress+Hauser Conducta GmbH+Co. KG

Dieselstraße 24

70839 Gerlingen

Germany

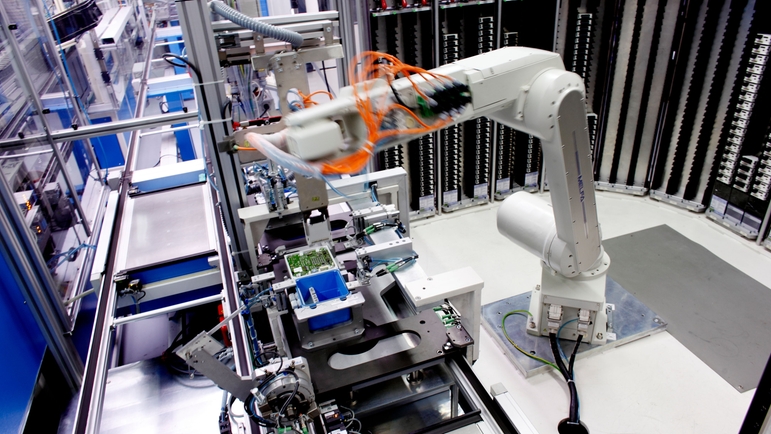

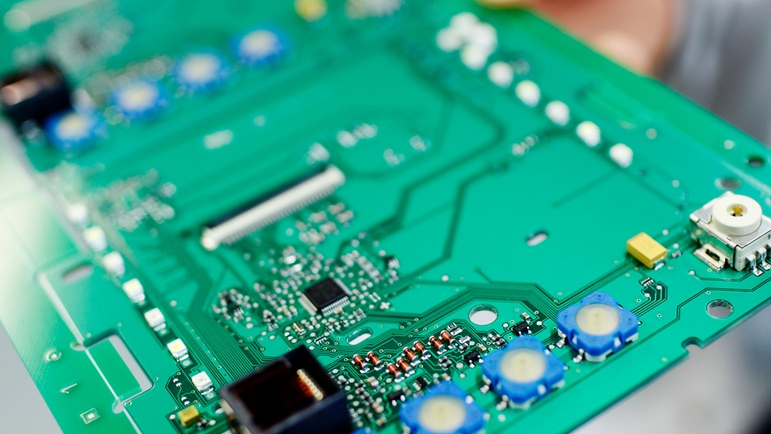

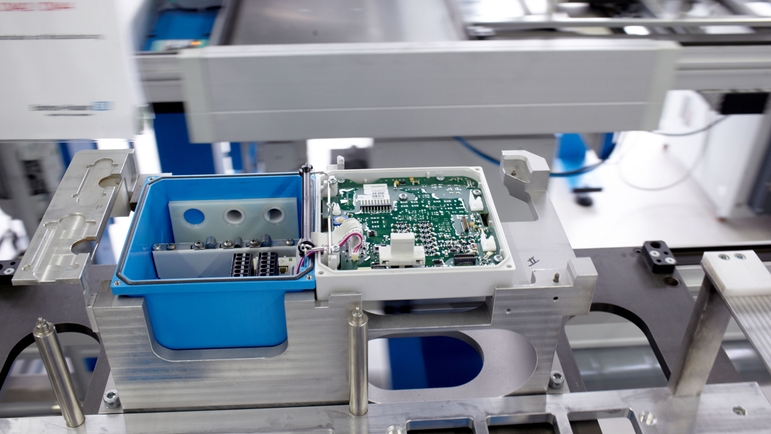

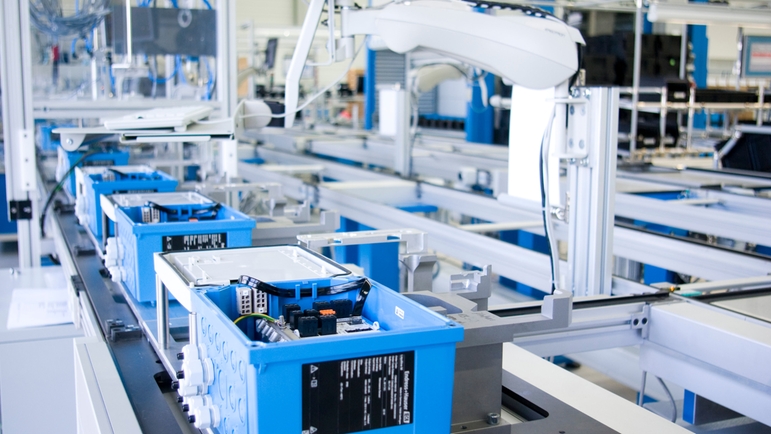

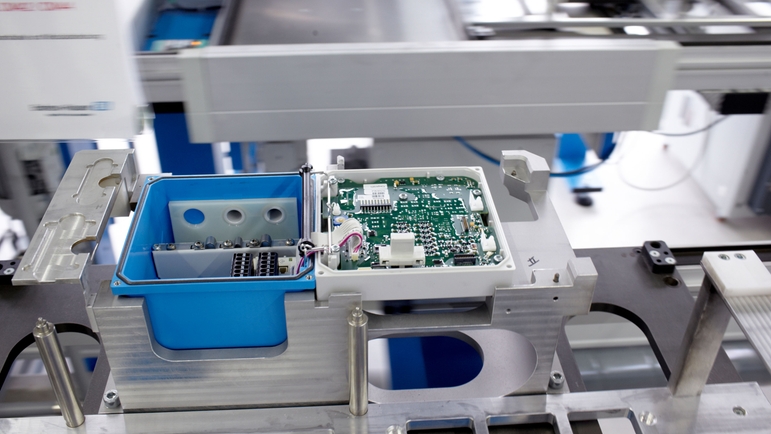

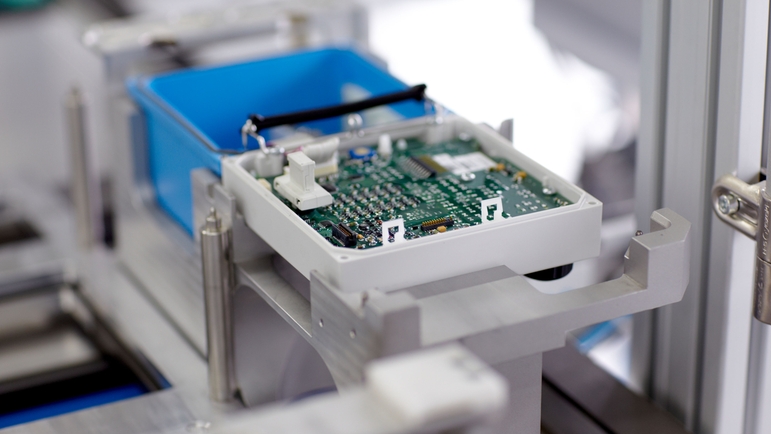

Liquiline production consists of an automated loop system where both transmitter types, Liquiline M CM42 and Liquiline CM44, are assembled. The system copies the information directly from the SAP order. A robot then places the appropriate modules and parts in the housing - even the nameplate with serial number and device-specific information is laser-engraved in a fully automatic process!

Before the devices are finished and the device-specific software installed, components have to be screwed and hinges must be mounted – and this is all done by hand. As a final step, all device functions are tested and the housing cover is put on. The finished Liquiline is then packed with the device-specific documentation ready for delivery.

Endress+Hauser Conducta GmbH+Co. KG

Endress+Hauser Conducta GmbH+Co. KG

Dieselstraße 24

70839 Gerlingen

Germany

Standard products

Technical excellence

Simplicity

Specialized products

Technical excellence

Simplicity

Variable

| FLEX selections | Technical excellence | Simplicity |

|---|---|---|

Fundamental selection Meet your basic measurement needs |

Technical excellence

|

Simplicity

|

Lean selection Handle your core processes easily |

Technical excellence

|

Simplicity

|

Extended selection Optimize your processes with innovative technologies |

Technical excellence

|

Simplicity

|

Xpert selection Master your most challenging applications |

Technical excellence

|

Simplicity

Variable |

We use cookies to enhance your browsing experience, collect statistics to optimize site functionality, and deliver tailored advertisements or content.

By selecting "Accept all", you consent to our use of cookies.

For further details please review our cookie policy .